The need for processing components with controlled porosity and/or multi-material composition is strong in many areas of application. The powder route is often mandatory or preferred for obtaining such components. Our activity in this field is very diversified, involving the processing and characterization of various materials for energy or medicine with the help, if required, of numerical tools, as DEM simulation.

Powder metallurgy in integrated systems

In close contact with G2Elab, the Grenoble Electrical Engineering Laboratory, we contribute to the improvement of packaging in power electronic devices by investigating the processing of heat exchangers and interface materials. The concept of “integrated sintering” has been introduced in this research, to deal with specific aspects of interfacial processes and interfacial stresses during the sintering of a powder material embedded in a system.

SEM micrograph of a joint processed by pressureless sintering of an Ag-paste, to be integrated in a power device, Nicolas Botter PhD. Thesis, coll. SAFRAN.

Schematics of an integrated cooling system, including the image of a porous copper material processed by powder sintering, IDEX-funded COOLPACK project, Joseph Glass PhD. Thesis, coll. G2Elab & LEGI

Sintered components with tailored porosity

As part of a collaboration with UMSHN university, Morelia, Mexico, components mimicking human bones are processed by pressing and sintering of Ti-based alloy powders. To obtain high and controlled porosity, pore formers are mixed with powder particles before pressing and next eliminated before sintering. The materials are characterized in terms of microstructure, mechanical properties and permeability.

Sintered Ti6Al4V alloy for orthopaedic application obtained by using pore formers. Cabezas-Villa et al., J. Mater. Res. 33 (2018) 650

Numerical analysis of the permeability of a component with non-uniform porosity

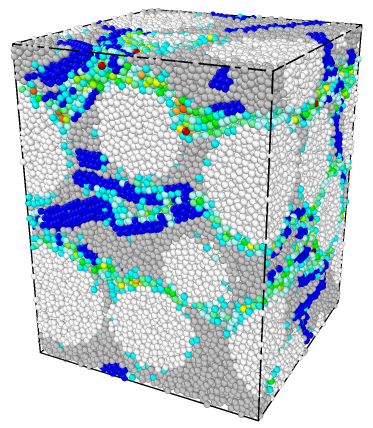

DEM simulation of the sintering of a powder containing large, artifical pores. T. Reynier et al., J. Euro. Ceram. Soc.,(2015)

Numerical simulation of compaction and sintering with in-house code dp3D.

Discrete Element simulations are used to capture the link between the microstructure at the scale of individual particles and the behaviour of the powder during processing. Complex microstructures, such as composites, powders with binder, or porous stuctures can be treated. The pertinent lenght scale may be the cristallite, the aggregate, the agglomerate or the whole compact. Close-die compaction, unloading, ejection and sintering are considered with a focus on defect initiation.

Compaction of a composite powder (PhD, Julia Bonaldo)

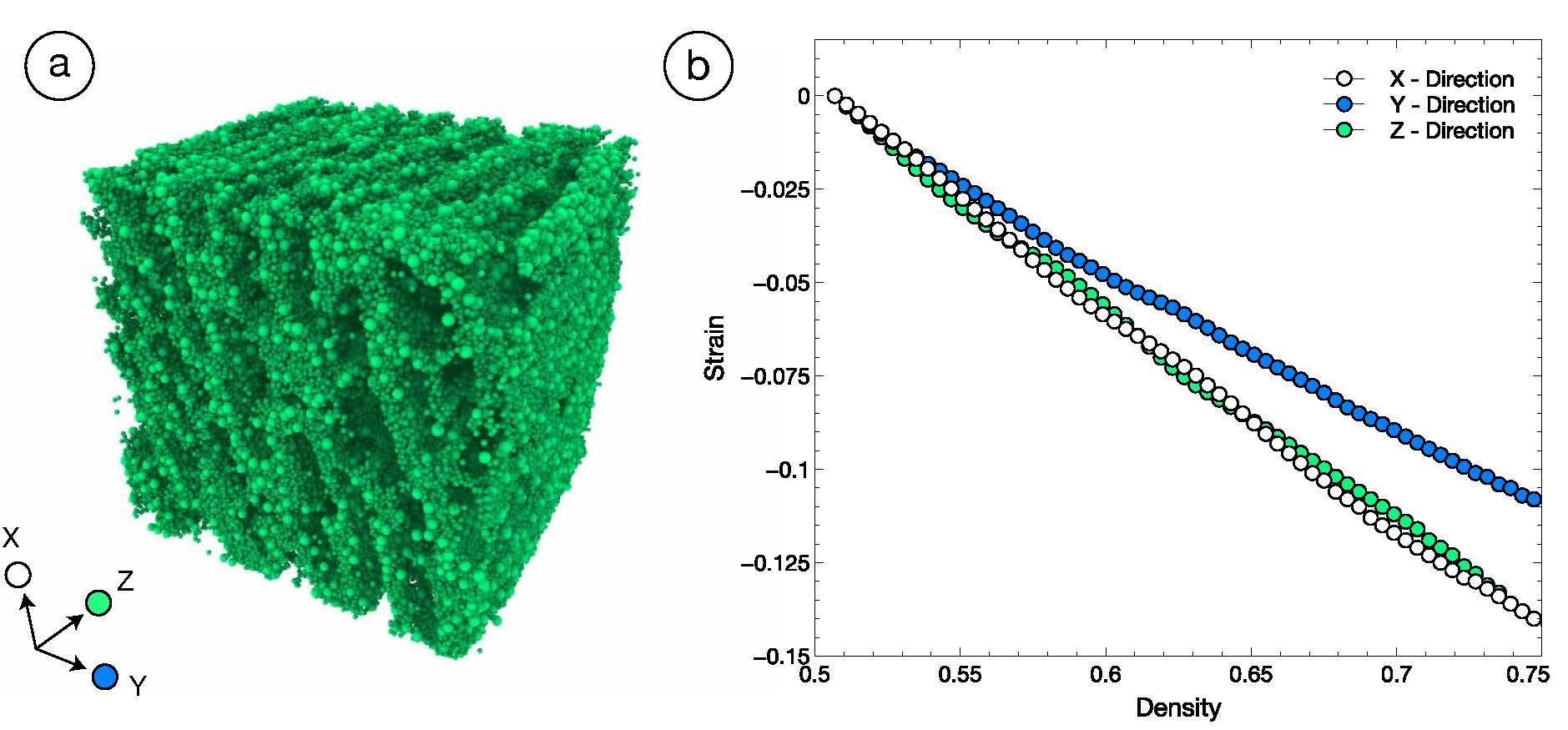

Anisotropic sintering of a freeze-cast structure. Collaboration with Univ. Washington and Clemson Univ.: Lichtner, A. et al. Acta Materialia (2018).

Nanostructured porous silica for thermal super-insulation

Silica aerogels, precipitated silica or fumed silica are highly nano-porous ( > 85%) materials used in super-insulation products (thermal conductivity < 25 mW.m-1.K-1). We investigate their mechanical behavior both experimentally and numerically at various scale levels. In fine, a better knowledge of their mechanical behavior and how to optimize it will help to find a better thermal/mechanical performance compromise for this class of materials. We are collaborating on this topic with MATeB (MATEIS / EDF) and Enersens.

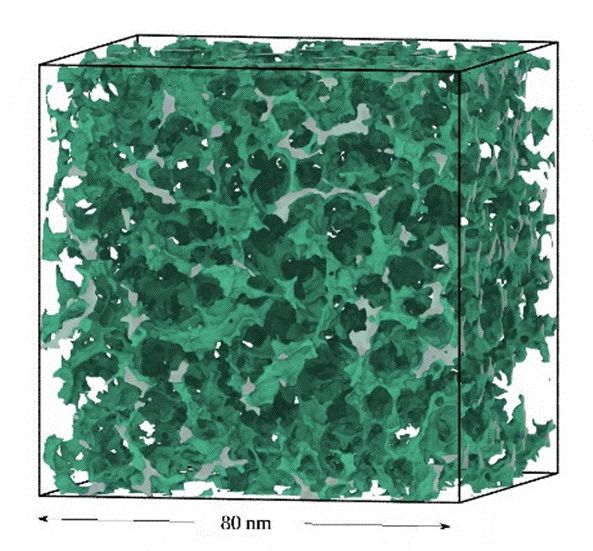

Molecular Dynamics (MD) of an aerogel sample. Investigation of mechanical behavior on large MD samples: Gonçalves et al., Acta Mater., 145 (2018) 165.

Discrete simulations of silica aggregates at the scale of primary particle reveal the origin of the radically different mechanical behavior of fumed and precipitated silica powders: Guesnet et al. B., J. Non-Cryst. Solids, 524 (2019) 119646.

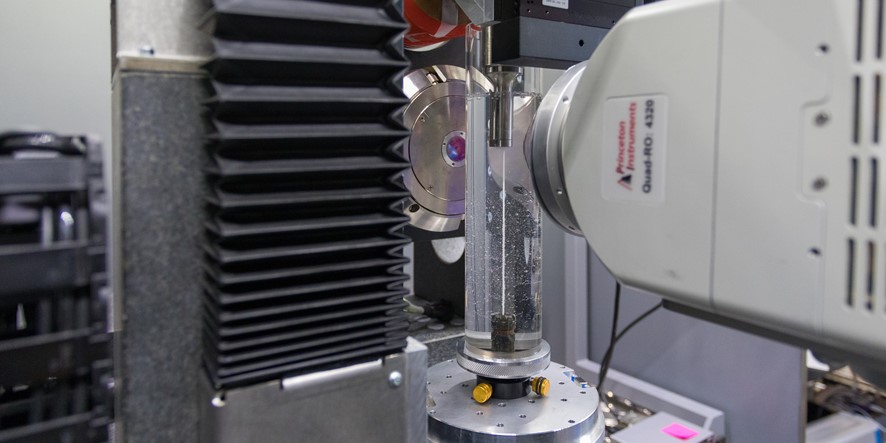

Super Insulation at Atmospheric Pressure (SIAP) composite panel (Aerogel + binder). In-situ X-ray tomography observation of crack propagation during Double Cleavage Drilled Compression (DCDC) test. Sample is 8x8x25 mm3. Guillaume Hamelin PhD. thesis, coll. MATEIS and Enersens.

Chercheurs / Enseignants-chercheurs

- Didier BOUVARD

- Jean-Marc CHAIX

- David JAUFFRES

- Christophe MARTIN

- Jean-Michel MISSIAEN

PhD and post-docs

Nicolas BOTTER (2021)

Robin GIBAUD (2017)

Joseph GLASS (2020)

Etienne GUESNET (2018)

Guillaume HAMELIN (2021)

Paul PARANT (2016)

Brayan PAREDES (2022)

Kaoutar RADI (2019)

Bruno SALQUE (2017)

Aatreya VENKATESH (2022)

Collaborations

Clemson University,

Forschungszentrum Jülich Institute of Energy and Climate Research,

ESRF The European Synchrotron,

CEA

MATEIS

UMSNH, Morelia, Mexico

G2Elab

LEGI

Projects

Mathegram

COMPASS

Funmat

CoolPack

CopperPack