dp3D is a DEM (Discrete Element Method) code dedicated to materials science. dp3D is an in-house code used for the numerical simuation of processes involving powders, and more generally for investigating the behavior of materials with a focus on brittle fracture. It comes with a series of contact laws that are useful for these domains (elasticity, adhesion, plasticity, sintering, bonding, fracture, continuum models, ...) and includes thermal conductivity.

dp3D comes with a user guide with case studies that are starting points for simulations. Although the development is mainly at SIMaP, the code is open to external users sharing interests in materials science (contact: Christophe Martin)

You can find here some examples of simulations using dp3D

dp3D comes with a user guide with case studies that are starting points for simulations. Although the development is mainly at SIMaP, the code is open to external users sharing interests in materials science (contact: Christophe Martin)

You can find here some examples of simulations using dp3D

Crushing of a porous aggregate

|

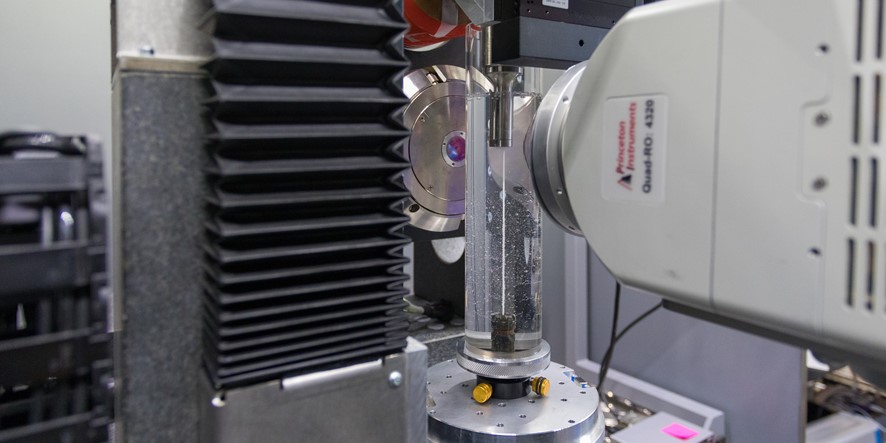

Using X-ray tomography for a numerical aggregate with internal defect |

Close-die compaction of aggregates |

Constrained sintering of a prenotched sample with grain-boundary limited diffusion

|

Crack extension during constrained viscous sintering

|

Temperature field induced by a moving energy source with associated sintering |

Thermal shock on a plate with crack growth and selection |

Crack growth in a alumina nacre, which microstructure originates from EBSD |

Buckling of a bar |

Selected Publications:

- Paredes-goyes, B., Jauffres, D. & Martin, C. L. A Level Set Discrete Element Model for sintering with an optimization-based contact detection. J. Theor. Comput. Appl. Mech. 0–18 (2025) doi:10.46298/jtcam.13721.

- Paredes-Goyes, B., Venkatesh, A. M., Jauffres, D. & Martin, C. L. Two-step sintering of alumina nano-powders: A discrete element study. J. Eur. Ceram. Soc. 43, 501–509 (2022).

- Paredes-Goyes, B., Jauffres, D., Missiaen, J.-M. & Martin, C. L. Grain growth in sintering: a discrete element model on large packings. Acta Mater. 218, 117182 (2021).

- Hamelin, G., Jauffrès, D., Martin, C. L., Meille, S. & Foray, G. Mechanical properties of milimetric silica aerogel particles produced through evaporative drying : A coupled experimental and discrete element approach. J. Non. Cryst. Solids 560, 120727 (2021).

- G. Hamelin, D. Jauffrès, C. L. Martin, S. Meille, and G. Foray, Mechanical properties of milimetric silica aerogel particles produced through evaporative drying : A coupled experimental and discrete element approach, Journal of Non-Crystalline Solids, vol. 560, no. December 2020, p. 120727, 2021.

- K. Radi, D. Jauffres, S. Deville, and C. L. Martin, Strength and toughness trade-off optimization of nacre-like ceramic composites, Composites Part B, vol. 183, p. 107699, 2020.

- K. Radi, D. Jauffrès, S. Deville, & C. L. Martin, Elasticity and fracture of brick and mortar materials using discrete element simulations. Journal of the Mechanics and Physics of Solids 126, 101–116, 2019.

- E. Guesnet, B. Bénane, D. Jauffrès C. L. Martin, G.P. Baeza, G. Foray et al. Why fumed and precipitated silica have different mechanical behavior : Contribution of discrete element simulations. Journal of Non-Crystalline Solids. 2019.

- D. Jauffrès, C.L. Martin, R.K. Bordia, Design of strain tolerant porous microstructures – A case for controlled imperfection, Acta Mater. 148 193–201, 2018.

- D. Roussel, A. Lichtner, D. Jauffrès, J. Villanova, R.K. Bordia, and C.L. Martin, Strength of hierarchically porous ceramics : discrete simulations on X-ray nanotomography images, Scr. Mater., 113 250–253, 2016.

- R. Kumar, S. Rommel, D. Jauffrès, P. Lhuissier, and C.L. Martin, Effect of packing characteristics on the discrete element simulation of elasticity and buckling, Int. J. Mech. Sci., 110 14–21, 2016.

- L. Hedjazi, C.L. Martin, S. Guessasma, G. Della Valle, and R. Dendievel, Experimental investigation and discrete simulation of fragmentation in expanded breakfast cereals, Food Res. Int., 55 28–36, 2014.

- Z. Yan, C.L. Martin, O. Guillon, and D. Bouvard, Effect of size and homogeneity of rigid inclusions on the sintering of composites, Scr. Mater., 69 327–330, 2013.

- D. Jauffrès, C.L. Martin, A. Lichtner, and R.K. Bordia, Simulation of the toughness of partially sintered ceramics with realistic microstructures, Acta Mater., 60 4685–4694, 2012.

- X. Liu, C.L. Martin, D. Bouvard, S. Di Iorio, J. Laurencin, and G. Delette, Strength of Highly Porous Ceramic Electrodes, J. Am. Ceram. Soc., 94 3500–3508, 2011.

- P. Pizette, C.L. Martin, G. Delette, P. Sornay, and F. Sans, Compaction of aggregated ceramic powders: From contact laws to fracture and yield surfaces, Powder Technol., 198 240–250, 2010.

- C.L. Martin and R.K. Bordia, The effect of a substrate on the sintering of constrained films, Acta Mater., 57 549–558, 2009.

- C.L. Martin and R.K. Bordia, Influence of adhesion and friction on the geometry of packings of spherical particles, Phys. Rev. E, 77 31307, 2008.

- C.L. Martin, G. Delette, and D. Bouvard, Compaction of ceramic aggregated powders, J. Am. Ceram. Soc., 89 3379–3387, 2006.

- C.L. Martin, L.C.R. Schneider, L. Olmos, and D. Bouvard, Discrete element modeling of metallic powder sintering, Scr. Mater., 55 425–428, 2006.

- L.C.R. Schneider, C.L. Martin, Y. Bultel, D. Bouvard, and E.Siebert, Discrete modelling of the electrochemical performance of SOFC electrodes, Electrochim. Acta, 52 314–324, 2006.

- C.L. Martin, Elasticity, fracture and yielding of cold compacted metal powders, J. Mech. Phys. Solids, 52 1691–1717, 2004.

- C.L. Martin, D. Bouvard, and S. Shima, Study of particle rearrangement during powder compaction by the Discrete Element Method, J. Mech. Phys. Solids, 51 667–693, 2003.

Contact

Retour à Matériaux divisés

- Matériaux divisés