Although Finite Element simulations are routinely used at GPM2, implementing Discrete simulations is a specific feature of the group. In-house codes have been developed for several years based on Discrete Dislocation Dynamics (TRIDIS, NUMODIS) or Discrete Element Methods (dp3D). More recently, Smoothed Particles Hydrodynamics (SPH) simulations have been developed for the study of cavitation erosion. These codes provide powerful tools for investigating plasticity, damage and fracture mechanisms.

Discrete Dislocation Dynamics simulations

3D Discrete Dislocation Dynamics simulations have been developed in SIMaP since 1990's. Following the pioneering work of Y. Brechet, G. Canova and L. Kubin, the edge-screw code TRIDIS has been developed and widely distributed so that it is currently used in many groups in the world. More recently, the project NUMODIS realized in collaboration with L. Dupuy (CEA Saclay) and M. Blétry (ICMPE Paris XIII) has led to the modern nodal dislocation code aNUMODIS (a Numerical Model of Dislocations) where the physics has been improved.

Examples of TRIDIS simulations of the creep behavior of Ni superalloys studied in collaboration with Bochum University (Ph.D. S. Gao 2016). For these simulations the grain shape is determined by phase field computations and the lattice mismatch is calculated using a FFT procedure.

Crack/Dislocation interactions (ERC project MicroK1c)

Within the framework of the ERC Consolidator Grant MicroK1c led by Erik BITZEK (FAU Erlangen-Nürmberg), TRIDIS code is used to model the propagation of cracks. The modeling uses the X-FEM approach already implemented in CAST3M2018 (www.cast3M.cea.fr) which has been coupled to TRIDIS via esope operators. The objective is to understand the interaction between dislocations and cracks and to compare DDD simulation results to experiments performed at FAU on a notched cantilever (Ph.D. E. Jover-Carrasco 2020).

Ultra High Cycle Fatigue Simulations (ERC project FastMat)

Both TRIDIS and NUMODIS are involved in the ERC Consolidator Grant project FastMat (Fast determination of fatigue properties of materials beyond one billion cycles) led by Nicolas RANC (PIMM, ENSAM ParisTech). The goal of FastMat is to develop a new method that reduces considerably the duration of fatigue characterization. This method involves the use of only short interrupted tests coupled with a self-heating measurement to characterize the fatigue behavior for very low stress amplitudes. The scientific objective is to develop simultaneously experimental and numerical tools for the fast determination of fatigue behavior. The experimental approach estimates simultaneously the dissipation and the stored energy, which directly reflect fatigue damage. For the numerical approach, discrete dislocation dynamics simulations are developed to establish links between the fatigue damage associated with the evolution of dislocation structures, the stored energy and the dissipated energy. Regarding DDD simulations, the irreversibility in the case of High Cycle fatigue (low stress amplitude) is strongly related to the probability of cross-slip events. The challenge is then to introduce a physically based rule for cross-slip in the DD model (Ph.D. M. Longsworth 2021).

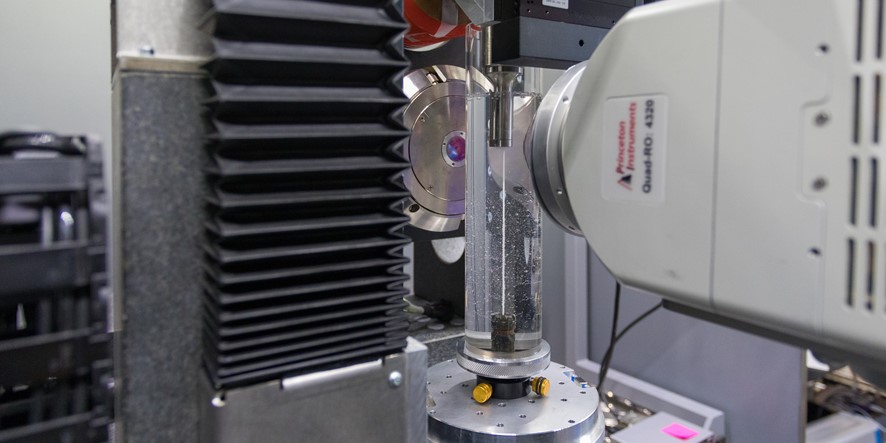

Smoothed Particles Hydrodynamics simulations

SPH model solves continuum equations based on the discretization of the space in representative particles. At SIMaP we started developping an axysimmetric version of the open-source code SPHysics and we implemented elasto-visco-plastic constitutive equations in order to solve plasticity problems.

Mass loss prediction in cavitation erosion could be predicted by numerical simulations provided the coupling between the cavitating fluid and the elasto-visco-plastic solid is accurately taken into account. This fluid/structure interaction problem has been succesfully solved using Smoothed Particules Hydrodynamics (SPH) simulations which account both for the fluid part and the solid part in the same code (Ph.D. S. Joshi 2018). SPH is also able to predict crack nucleation and propoagation as shown in the tensile test simulation above (right).

Discrete Element simulations

DEM simulations are used to simulate fracture in porous and dense ceramics, based on our in-house code dp3D. The aim is to understand the link between fracture, toughness and microstructure to design strain tolerant architectures.

Crack pattern evolution in a dense ceramic submitted to thermal shock.

Crack evolution in a notched alumina nacre. The initial microstructure originates from an EBSD image.

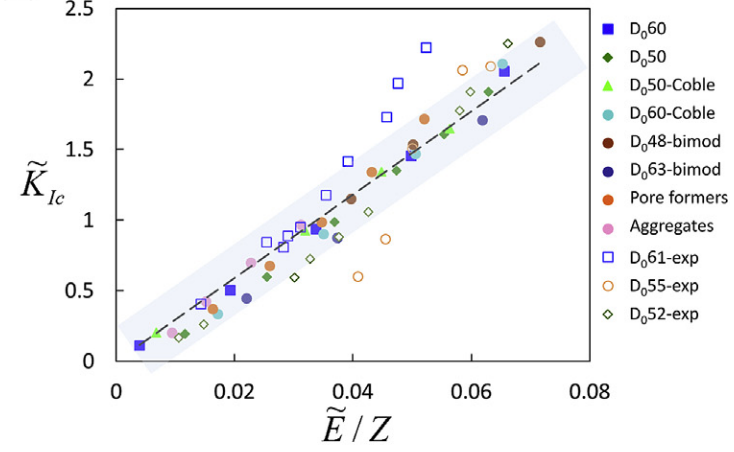

Scaling law relating toughness to the Young's modulus normalized by the number of bonds per particle in a porous ceramic.

Chercheurs / Enseignants-chercheurs

PhD and post-docs

Siwen GAO (2016)

Shrey JOSHI (2018)

Elena JOVER-CARRASC0 (2020)

Margarita LONGSWORTH (2021)

Fabien MENG (2020)

Jessica MUZY (2020)

Hareesh TUMMALA (2016)

Arjun VARMA (2022)

Discrete element simulations:

Julia BONALDO (2021)

Alexis BURR (2017)

Robin GIBAUD (2017)

Etienne GUESNET (2018)

Guillaume HAMELIN (2021)

Paul PARANT (2016)

Brayan PAREDES (2022)

Kaoutar RADI (2019)

Bruno SALQUE (2017)

Collaborations

Christian ROBERTSON and Laurent DUPUY (SRMA, CEA Saclay)

Marc BLETRY (ICMPE, Paris XII)

Hyung-Jun CHANG (SafranTech)

Laurent DELANNAY and Thomas PARDOEN (UCLouvain)

Anxin MA and Alexander HARTMAIER (ICAMS, Univ. Bochum, Germany)

Jean-Pierre FRANC, Giovanni GHIGLIOTTI (LEGI, Grenoble)

Nicolas RANC (PIMM, ENSAM Paristech)

Erik BITZEK (FAU Erlangen)

Khi Han KIM (ONR, USA)

Erik JOHNSEN (Michigan Univ, USA)

Raj Bordia (Clemson Univ, USA)

Zack Cordero (Rice Univ, USA)