Mechanical characterization

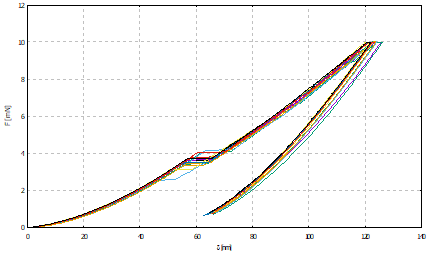

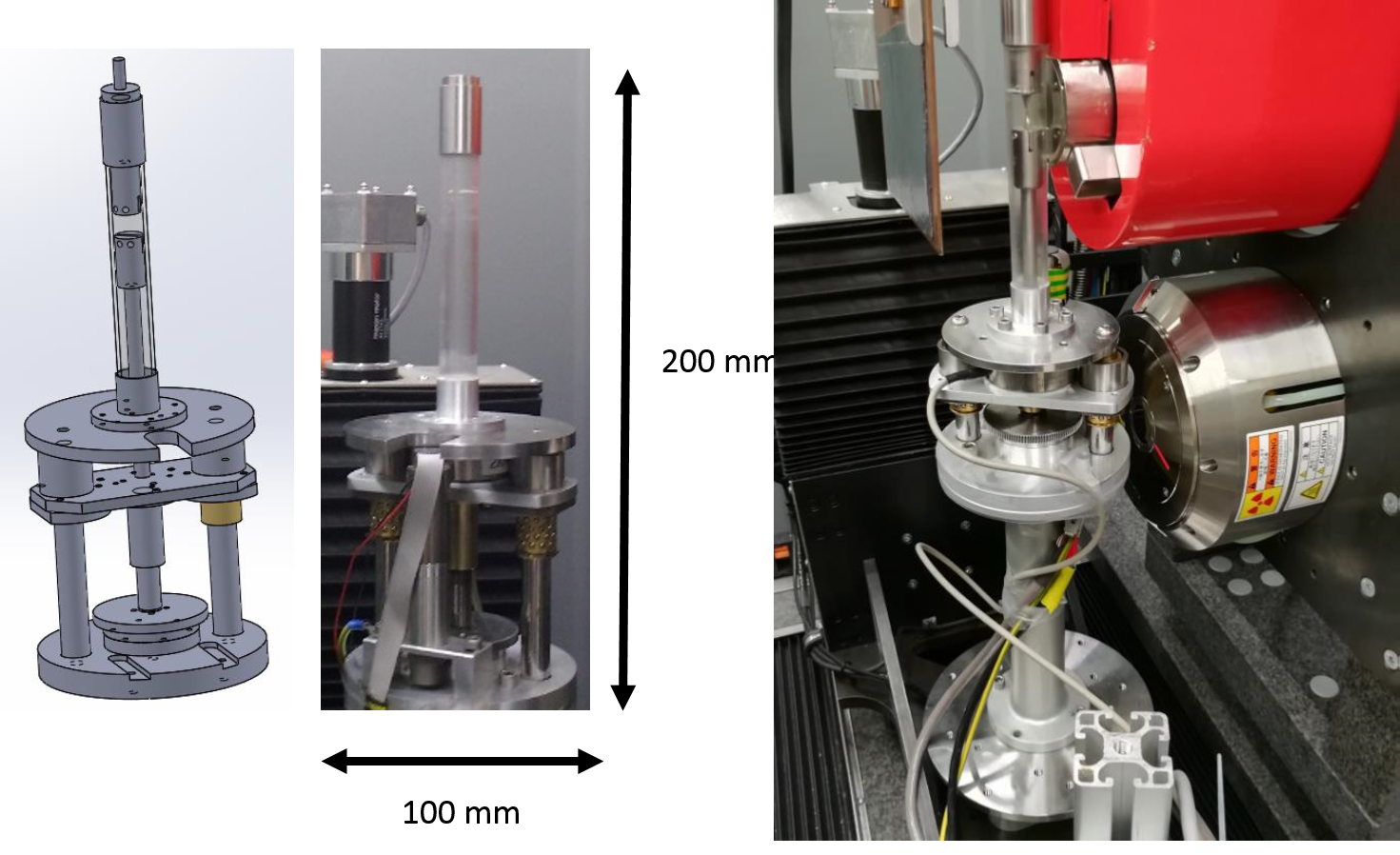

Tensile-Compression devices

• 10N-100KN

• various atmospheres and temperature ranges available

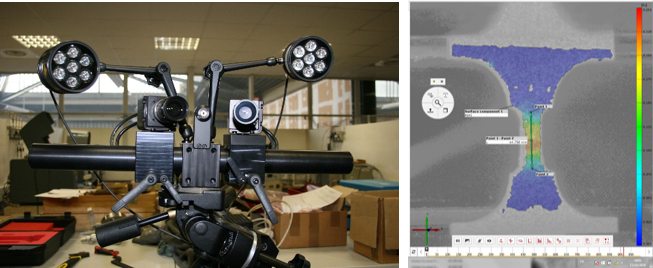

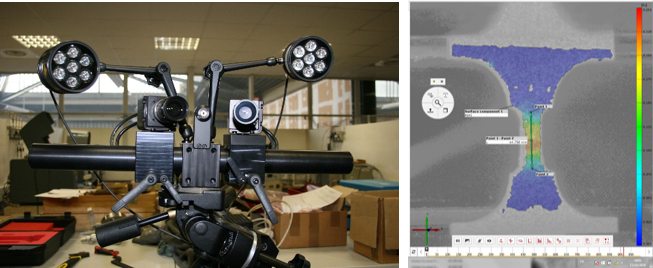

Strain measurement : GOM ARAMIS 6M

• 2.5D Motion and Deformation Sensor

• portable

• resolution: 1µm

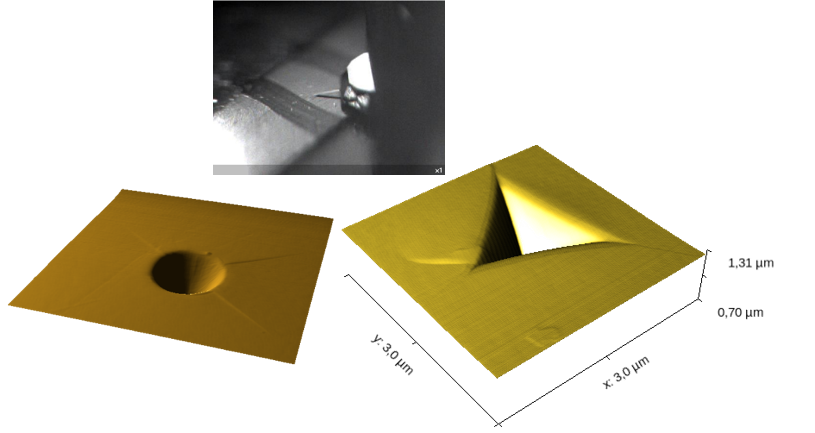

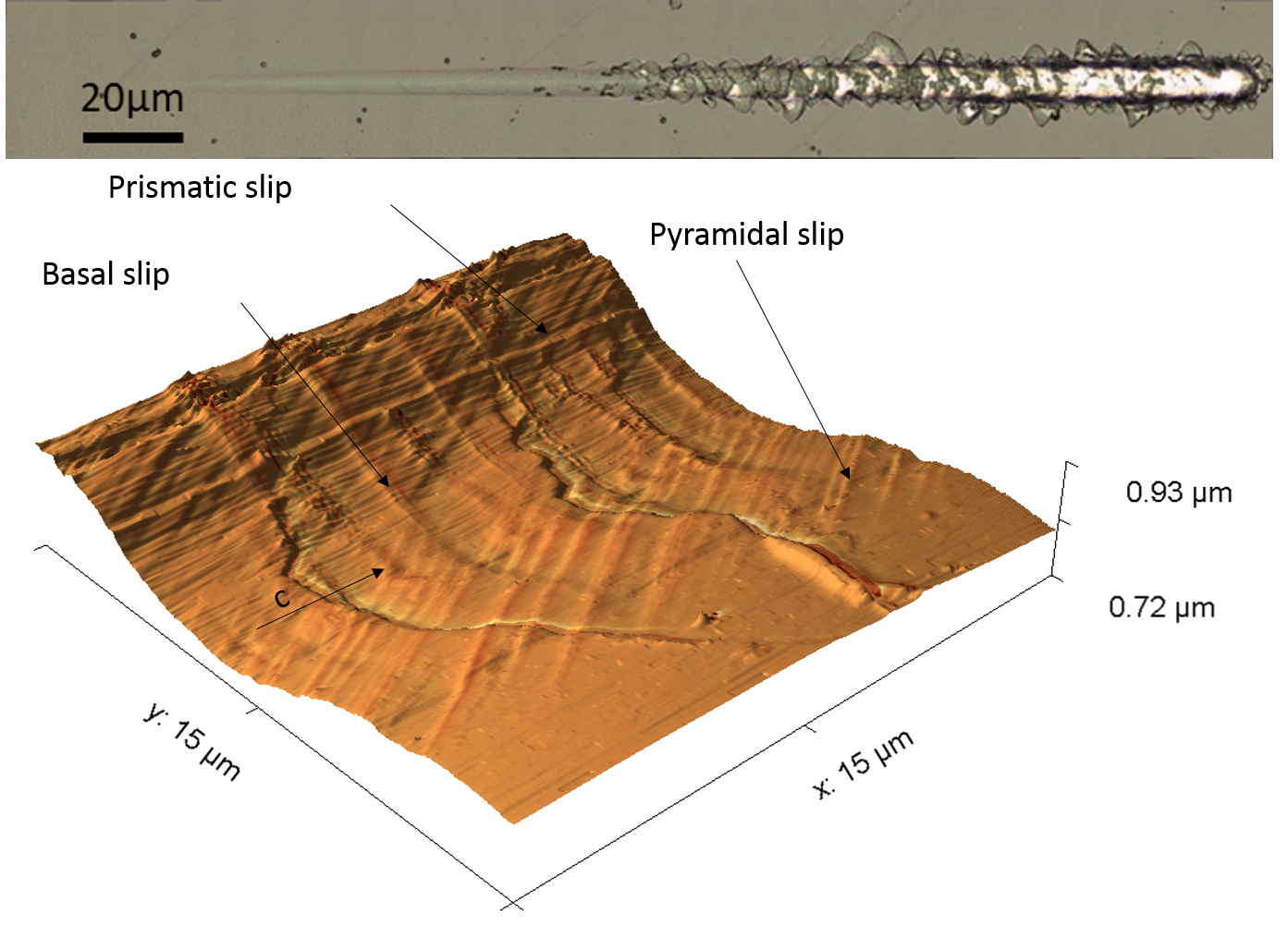

Compact Nanoindentation plateform (Anton PAAR STEP4) and Optics (x5 x20 x50 x100)

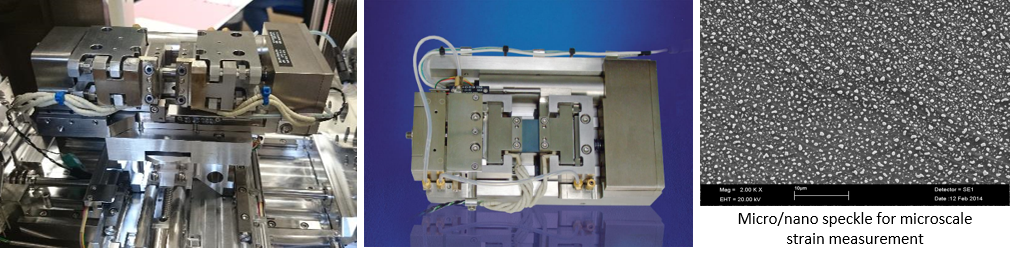

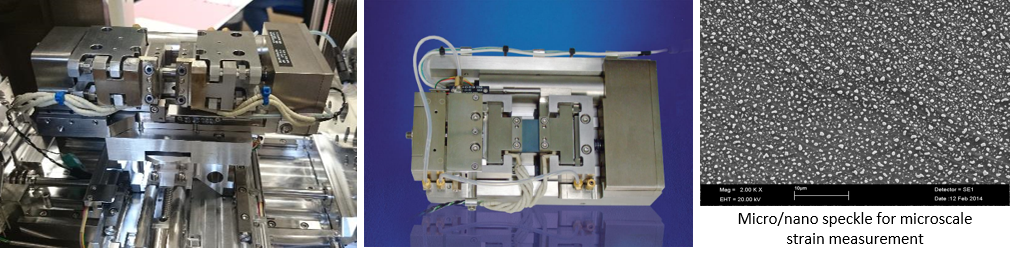

Tensile-compression in-situ device in SEM

• load cell 2000N & 5000N

• sample size: 29x27x5mm (LxBxH)

• Tmax=500°C

• 10N-100KN

• various atmospheres and temperature ranges available

Strain measurement : GOM ARAMIS 6M

• 2.5D Motion and Deformation Sensor

• portable

• resolution: 1µm

Compact Nanoindentation plateform (Anton PAAR STEP4) and Optics (x5 x20 x50 x100)

| Ultra Nano Hardness Tester (UNHT3) | Wide Scan Atomic Force Microscope (AFM) | Micro Combi Tester (MCT3) |

| • Negligible thermal drift • Depth resolution : 0,001nm • Load resolution : 0,01µN • Max load : 100mN • Max depth 50µm • Tips : - Berkovich - Cube corner - Spheres (1µm & 10µm)  |

• Scan area 110 µm x 110 µm • Max vertical depth 22µm • Optical top and side view of the cantilever • Contact mode and Non contact dynamic mode • Dynamic frequency range 15-300kHz  |

• Micro scratch + Microindentation • Max Load : 30N • Max Friction Load : 30N • Max penetration depth : 1mm • Max scratch length : 4mm • Tips : - Sphere 100µm (scratch) - Vickers (indentation)  |

• load cell 2000N & 5000N

• sample size: 29x27x5mm (LxBxH)

• Tmax=500°C

Microstructural characterization

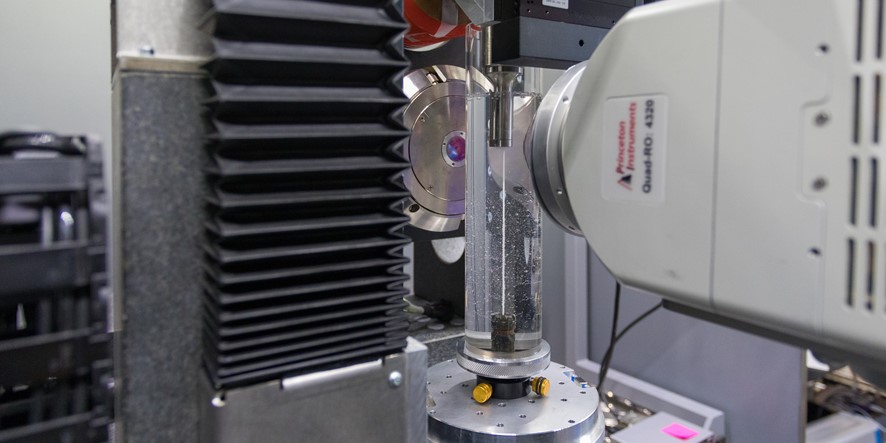

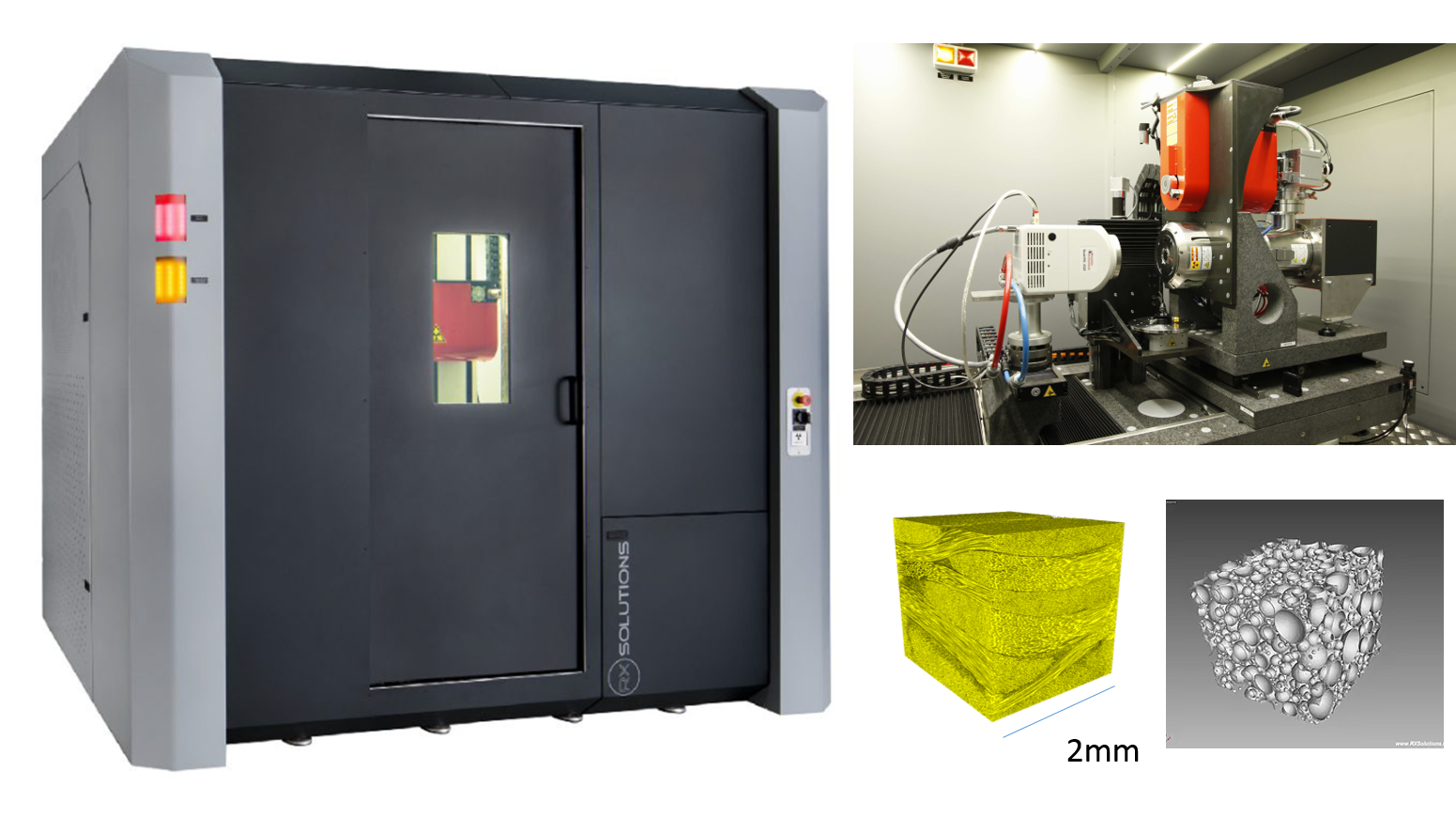

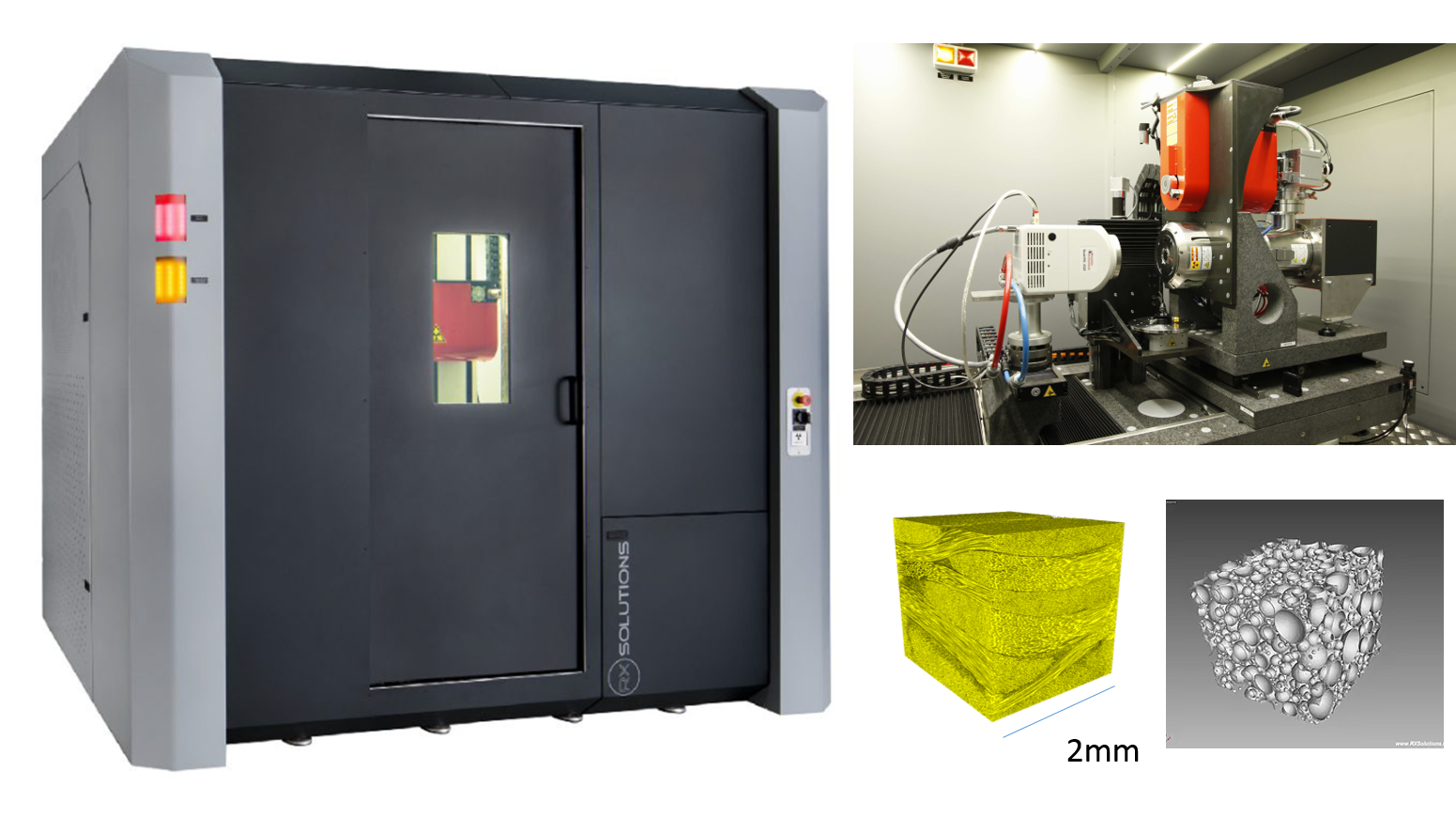

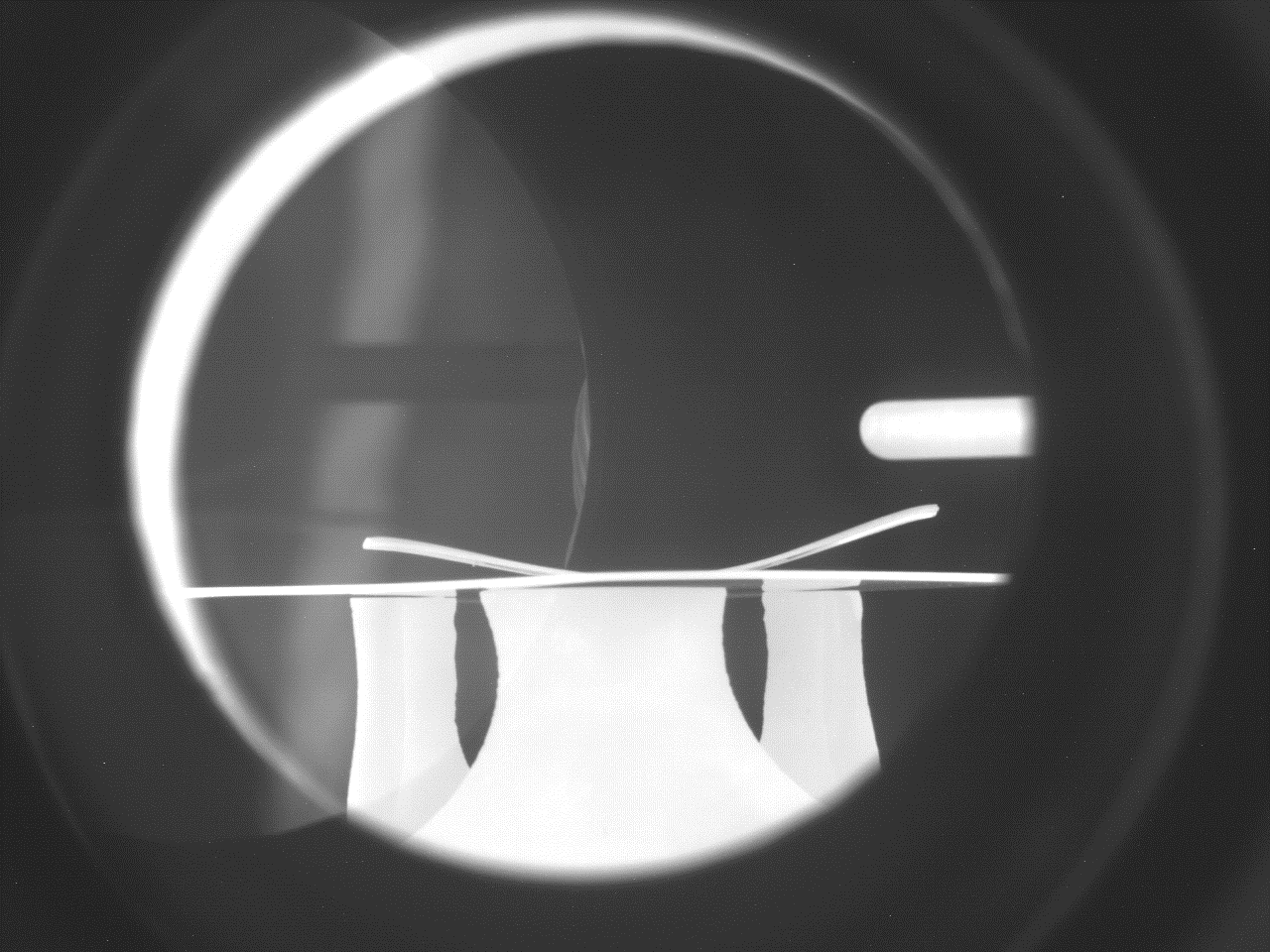

X-ray nanotomography: RX solutions

• resolution: 0.25µm – 100µm

• ex-situ or post-mortem characterization

• multi-partners facility (UGA)

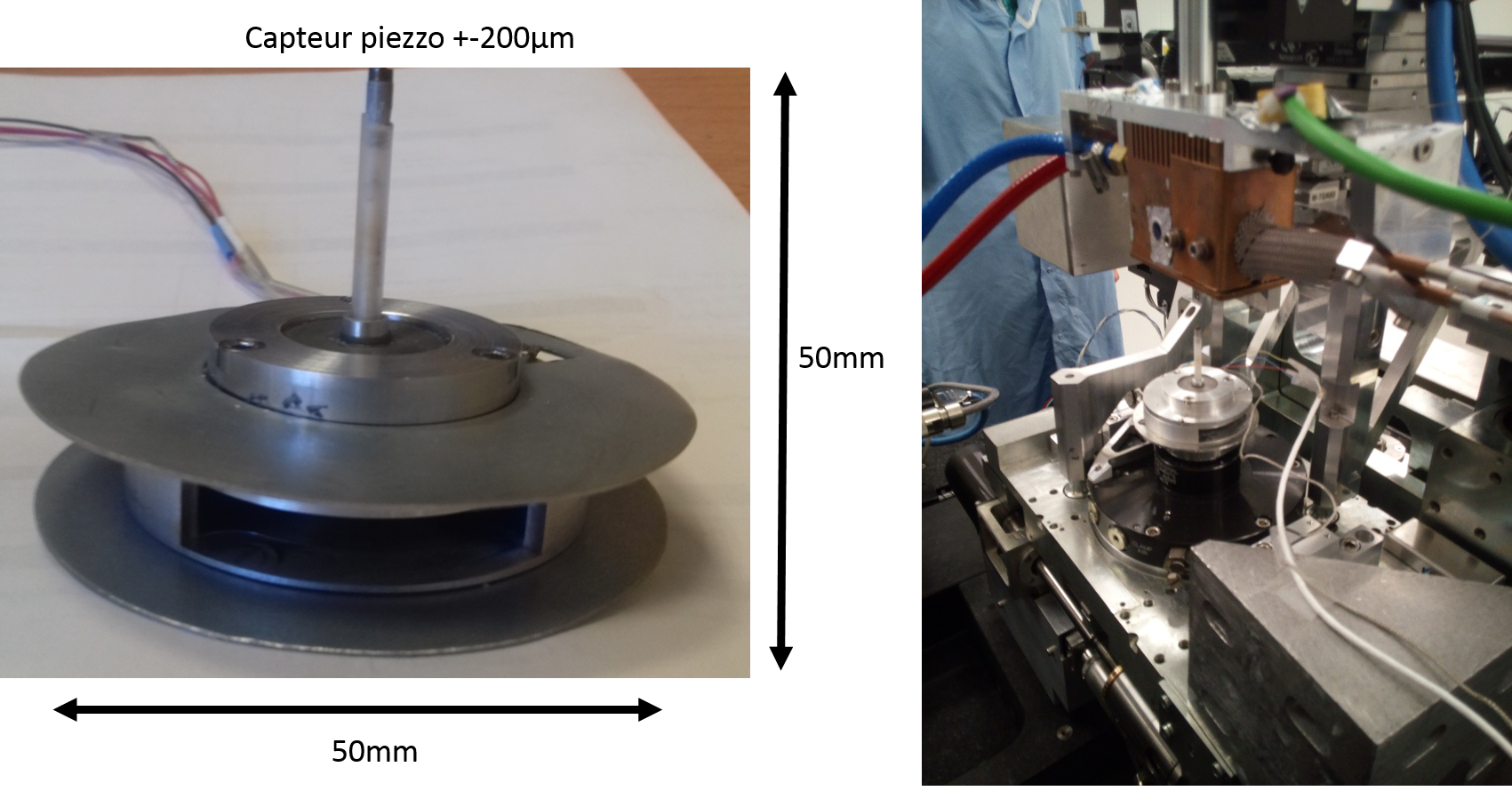

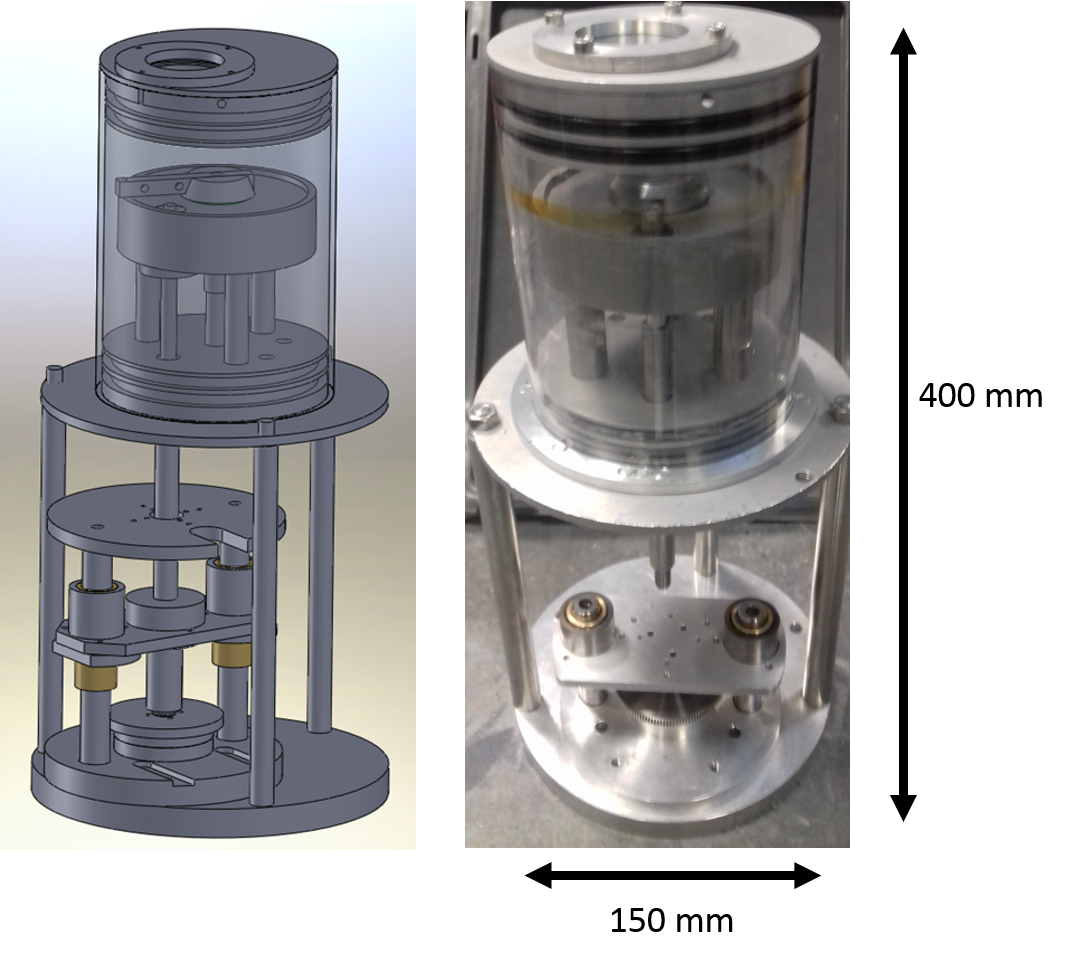

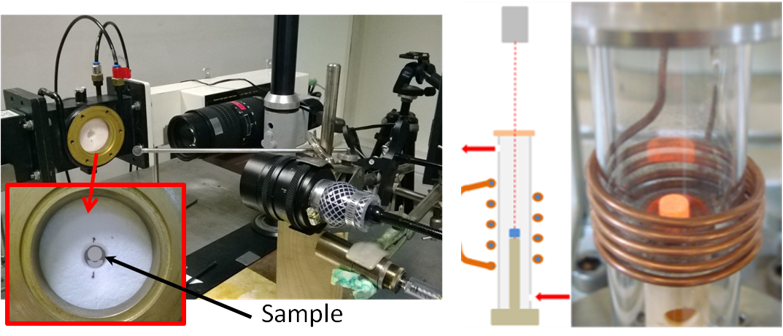

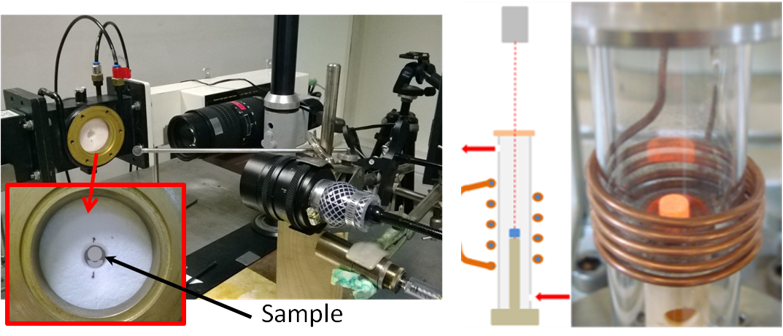

In-situ thermo-mechanical characterization developments

Dilatometry

• Optical Dilatometry with constrained sintering (load 50 N)

• TMA, TGA, TDA

• various atmospheres

• ceramics, metals

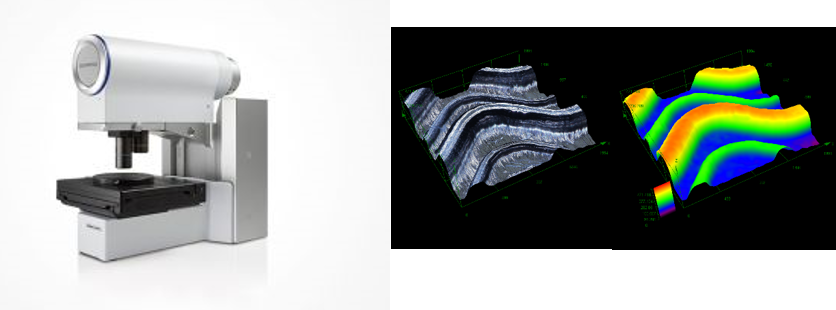

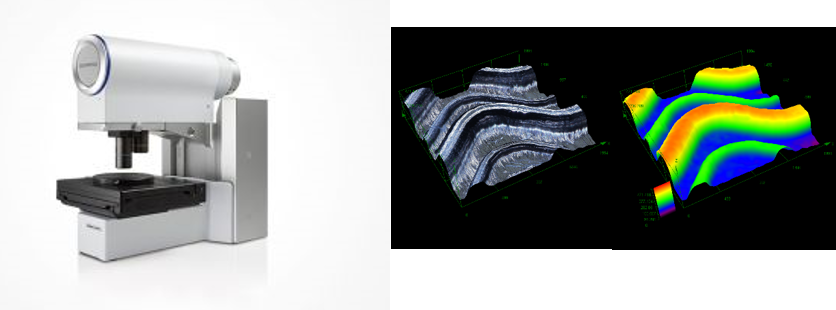

Digital microscope, Olympus DSX 510

• resolution 200 nm

• large image capture possibilities

• 2D and 3D image capture

• resolution: 0.25µm – 100µm

• ex-situ or post-mortem characterization

• multi-partners facility (UGA)

In-situ thermo-mechanical characterization developments

|

nanotomography

|

microtomography

|

microtomography with additionnal manufacturing |

• Optical Dilatometry with constrained sintering (load 50 N)

• TMA, TGA, TDA

• various atmospheres

• ceramics, metals

|

|

|

Digital microscope, Olympus DSX 510

• resolution 200 nm

• large image capture possibilities

• 2D and 3D image capture

Material processing

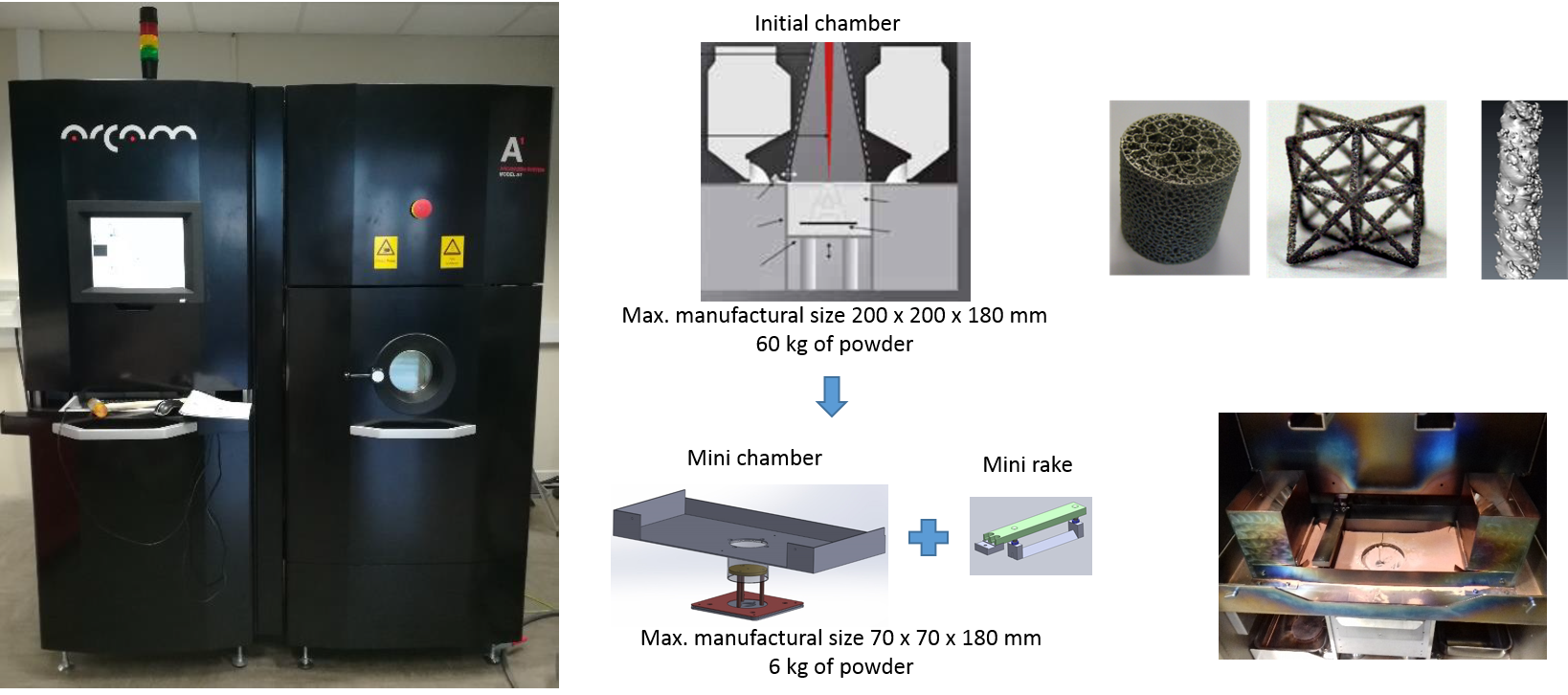

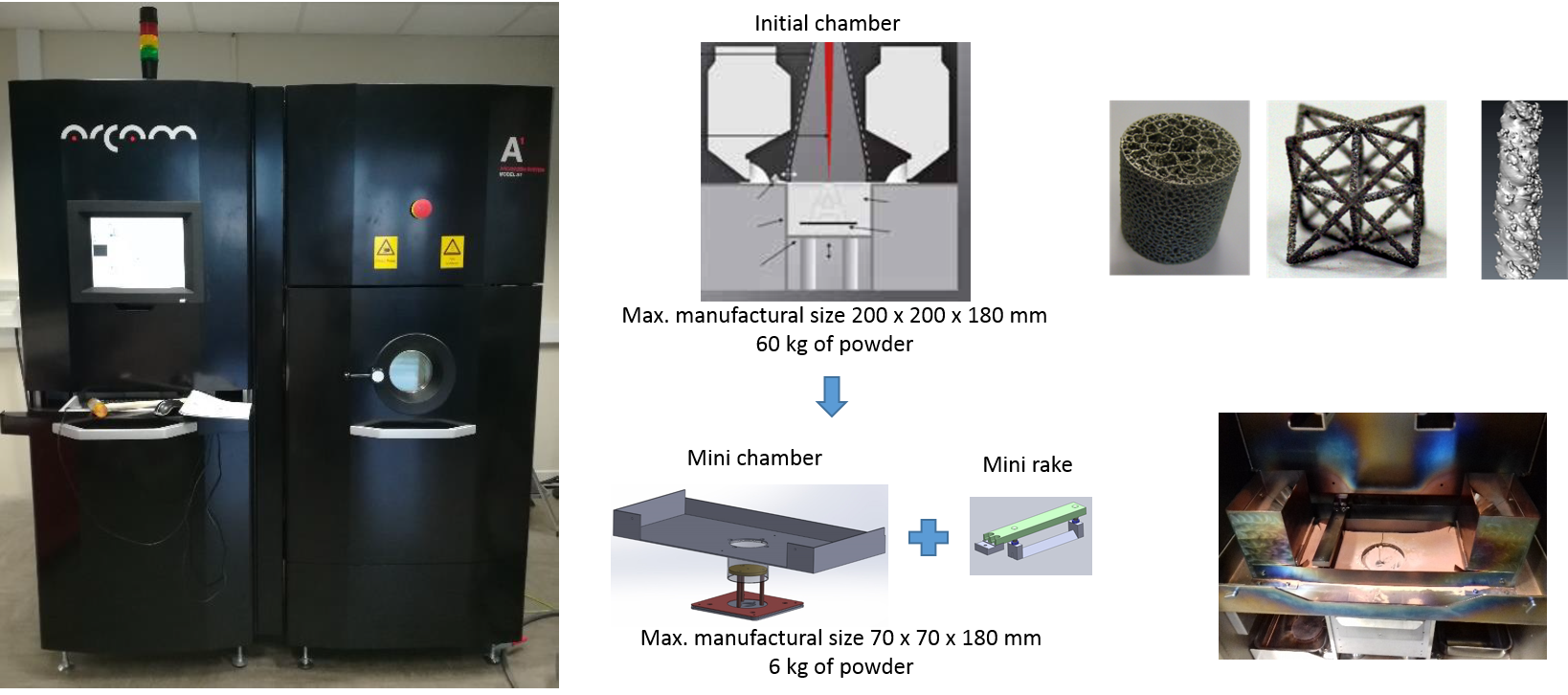

Additive manufacturing: Electron Beam Melting

• Two ARCAM A1 EBM machines

• Titanium alloys, new materials (Cu, Al, …)

• in-situ characterization

Conventional, Induction and microwave sintering

• direct induction heating

• microwave

• metal, ceramics powders

Amorphous metallic alloys

• ultra pure material elaboration

• injection

• surface texturation

• strong link with VULKAM start-up for processing

• Two ARCAM A1 EBM machines

• Titanium alloys, new materials (Cu, Al, …)

• in-situ characterization

Conventional, Induction and microwave sintering

• direct induction heating

• microwave

• metal, ceramics powders

Amorphous metallic alloys

• ultra pure material elaboration

• injection

• surface texturation

• strong link with VULKAM start-up for processing

Personnel technique