Lattice structures can be defined as spatially controlled assemblies of struts or beams. These structures appear as the archetype of architectural materials that can be obtained by AM (additive manufacturing). Fields of application are diverse : weight saving, energy absorption, heat exchange, hosting structures, new behaviours. Some specific issues addressed in the team are given below.

To do WITH defects inherited from the process

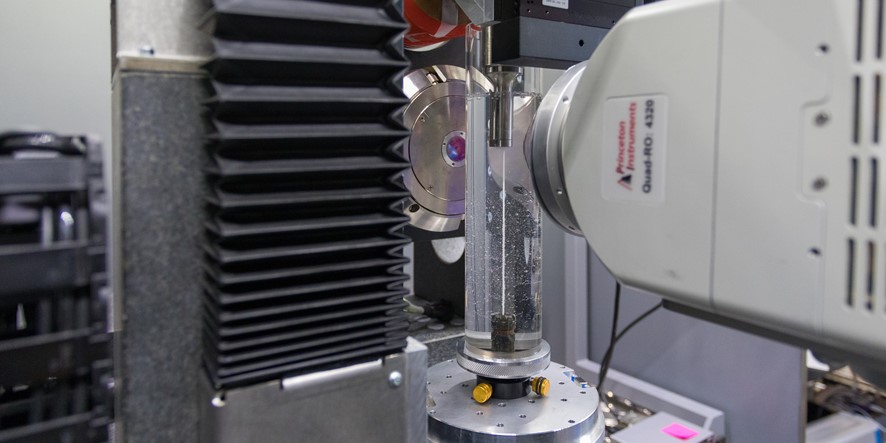

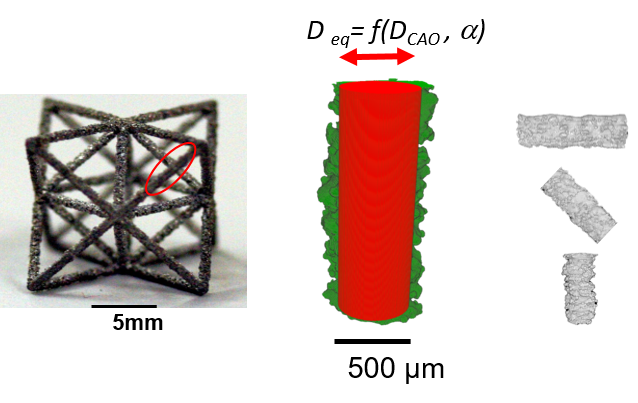

AM and in particular EBM results in different type of defects for as-built parts: surface defects (plate-pile like defects, powders stuck to the surface or partially melted) , internal defects (entrapped gas, lack of fusion ...). All these defects are detrimental for mechanical properties. Some post treatments can help : machining, chemical etching or ultrasonic shot peening for surface defects, Hot Isostatic Pressing for internal ones. When considering lattice structures, it is hard if not impossible to apply some of these post-treatments ans some defects may persist. Thanks to X-ray microtomography, we have defined some corrective factors in order to take into account these defects for static (Fig.1) or fatigue (Fig.2) behaviours.

Fig1 - definition of a mechanically equivalent diameter for single struts

Fig.2 Effect of different post-treatments (etching, HIP, Ultrasonic Shot Peening) on the fatigue properties of EBM single struts. Corresponding surface defects.

Lattices as hosting structures

As R. Feynman might have said, there is a plenty of room into a lattice structure. This can be filled in order to bring a new functionnality. Different examples are presented below.

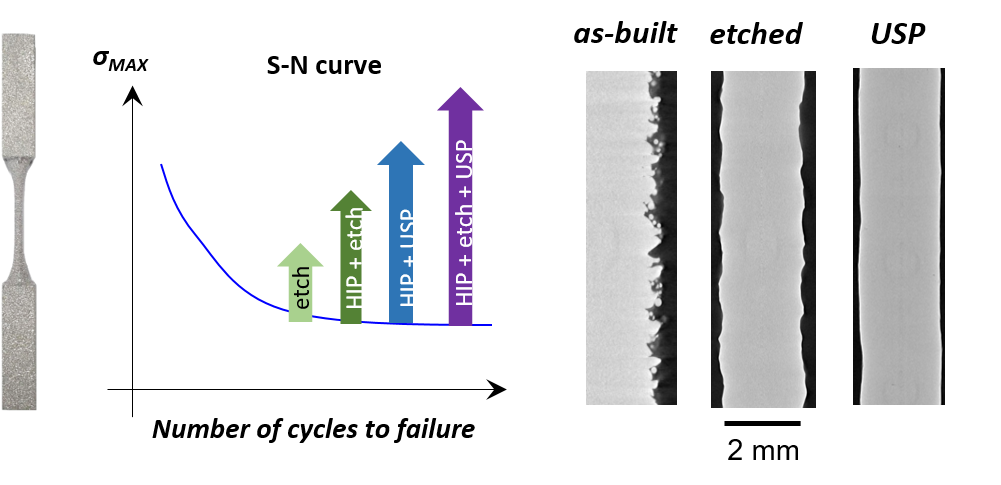

Ex.1 - Hybriding EBM (for the lattice) + Spark Plasma Sintering allows to fabricate complex metal/metal composites, with a dense matrix and a very good interface.

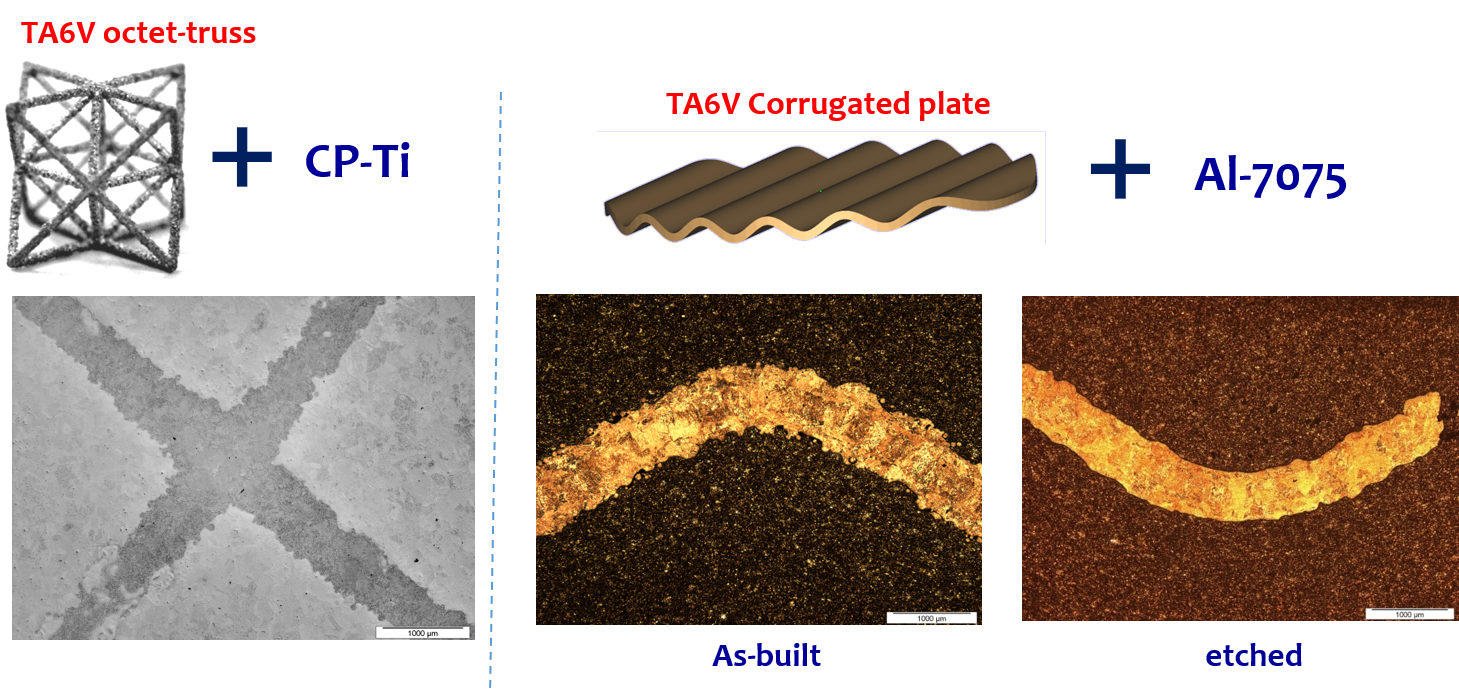

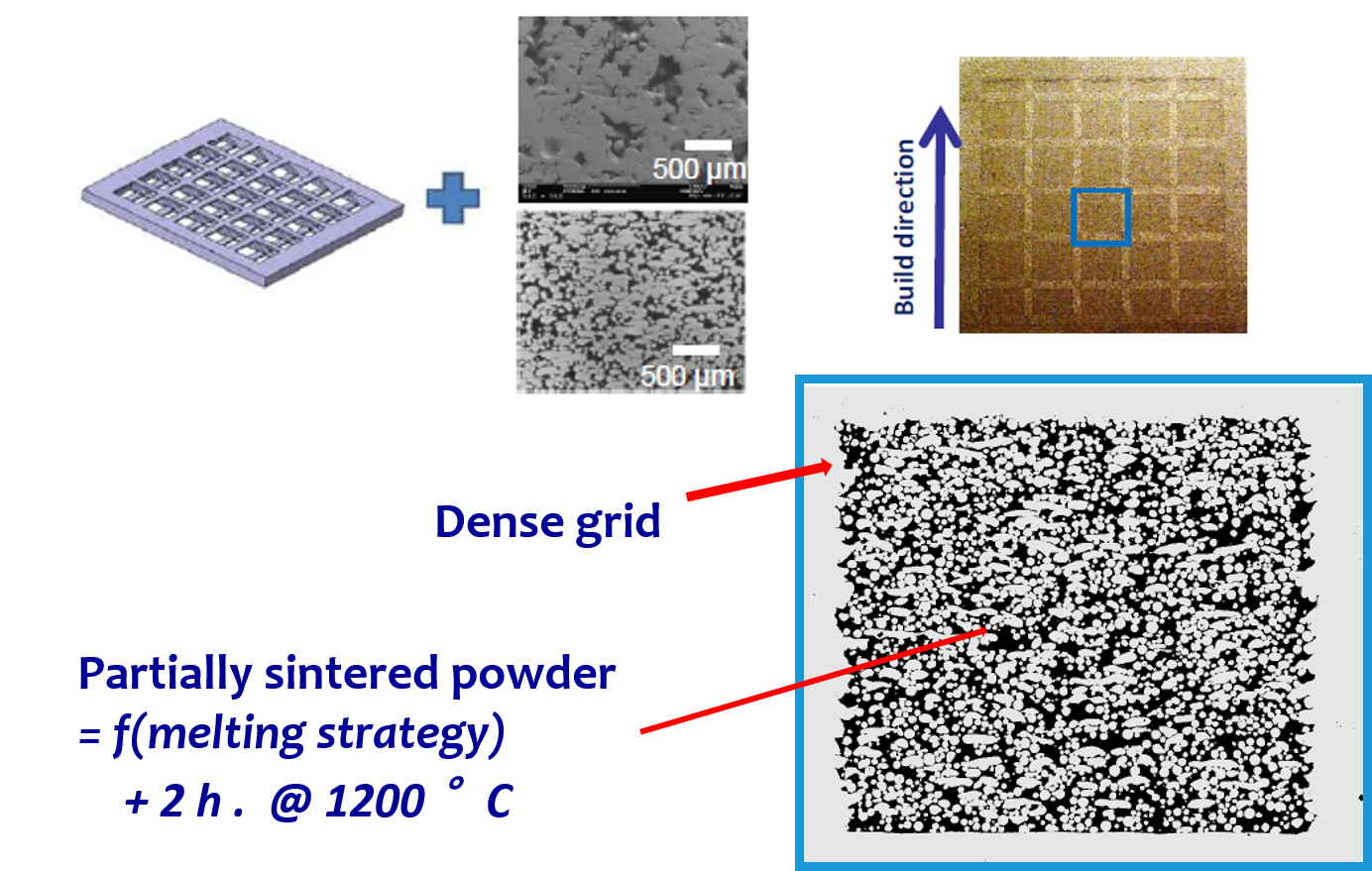

Ex. 2 - FIlling the lattice during the EBM process : degrading locally some energy parameters allows to create dense zones coexisting with porous ones. An example is a grid filled by a partially melted TA6V powder (coll. with ONERA for the concept of transpiration cooling of new combustion chambers)

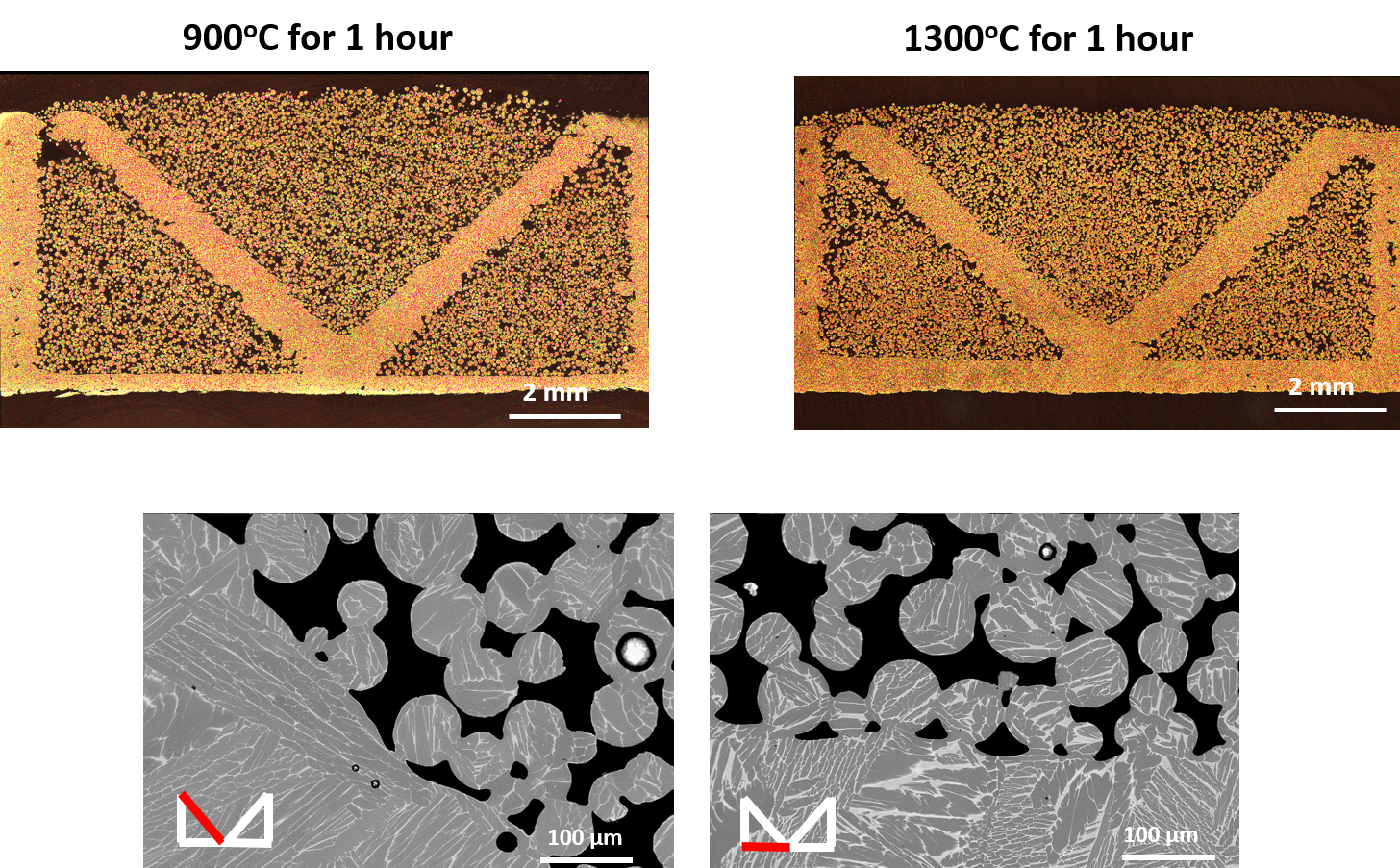

Ex.3 - Filling the lattice after the EBM process : here the case of an octet-truss lattice filled by a TA6V powder and then sintered for 1h : effect of the sintering temperature on the interface between the powders and the dense parts. Note the poor interface for down-facing parts.

Chercheurs / Enseignants-chercheurs

PhD and post-docs

Mathis DUPORT (2022)

Antalya HO-SHUI-LING (2018)

Hélène GOMEZ (2020)

Océane LAMBERT (2017)

Oleksii LIASHENKO (2018)

Sébastien PINSON (2016)

Emeric PLANCHER (post-doc 2019)

Charles THOUMYRE (2016)

Collaborations

LMGP : C. Picart,

MATEIS (INSA Lyon) : J.Y. Buffière, E. Maire ,

ULB : S. Godet,

ONERA : C. Davoine, M. Thomas,

AIRBUS,

Airbus Safran Launcher,

SAFRAN,

POLYSHAPE,

ZODIAC,

SINTERTECH,

AVNIR, ...

Projects

ANR MOSART,

FUI INCAS,

FUI PALOMA, …