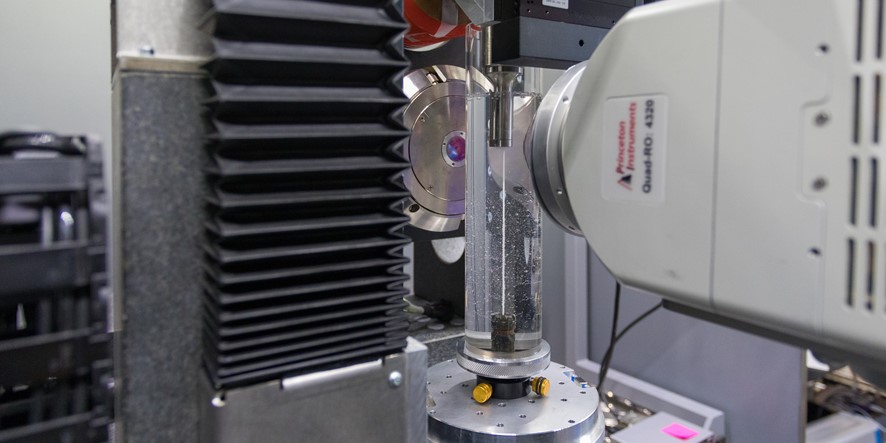

The work performed on high temperature deformation of metals (in particular in superplastic conditions) and composites is mainly experimental and uses most of the time in situ X-ray micro-tomography at the ESRF. Various kind of metals (aluminium alloys, magnesium alloys, steels) and composites (magnesium based nano-composites, bulk metallic glasses composites) have been investigated. Research focused in the main deformation mechanisms and in the study of damage nucleation and growth.

Bulk metallic glasses composites

Deformation mechanisms in bulk metallic glasses composites: in the framework of the ANR EDDAM project, we elaborated and studied the co-deformation of composites consisting in a copper matrix and Zr based bulk metallic glass inclusions. In situ tests combined with finite elements models allowed to investigate the relations between the deformation of the particles and the temperature and strain rate conditions.

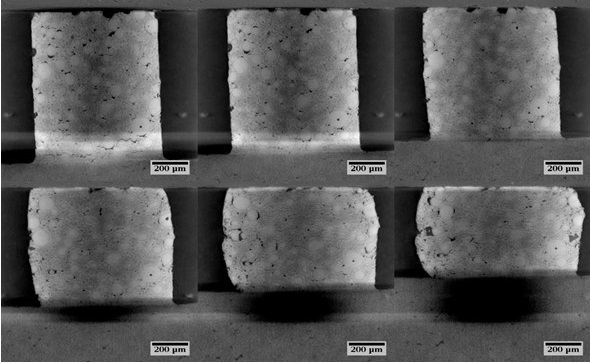

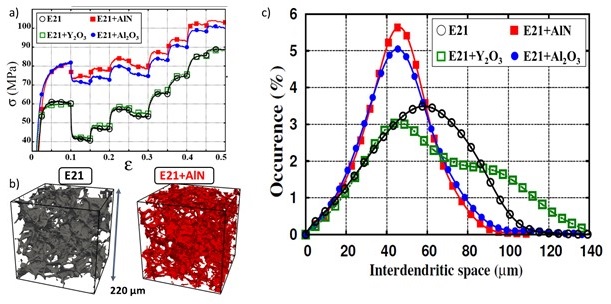

Deformation mechanisms in magnesium based nano-composites

Stress-strain jumps curves in compression at 350°C b) 3D rendering of intermetallics in E21 unreinforced and E21 reinforced with 1% of nano AlN c) interdendritic space obtained using 3D granulometry on 3D CT data.

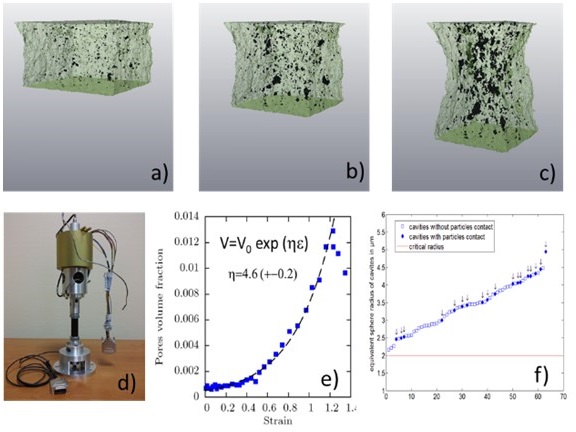

High temperature deformation and damage of magnesium alloys

High temperature deformation of AZ31. Figure a to c : 3D rendering for various strain. d) high temperature tensile device. e : cavities volume fraction with strain . f: interaction between cavities and particles.

We studied the growth and coalescence of cavities using in situ X-ray micro-tomography with a specific tensile machine (figure 2d) in an AZ31 alloy at 400°C for strain rates ranging from 10-3s-1 à 10-4s-1 (including conditions associated with superplastic properties) with a spatial resolution of the order of 1µm. It was possible to obtain macroscopic information (4D rendering and cavitation as shown in figurea to c and e) but also microscopic relations between cavities and particles : for example it was found that an large faction of cavities are not in contact with particles (figure f) and that the coalescence between cavities can start at very small strains. The effect of temperature on strain localization in Mg alloys is also studied thanks to a specific device allowing mechanical testing in SEM with appropriate image correlation techniques. The aim of this study is to identify the parameters controlling such localization (i.e. grain size, texture, competition between deformation mechanisms). Experimental results will be compared to EF simulations of crystalline plasticity performed in U.C. Louvain (Belgium).

Hot tearing behaviour of Al-Cu using in situ X-ray microtomography

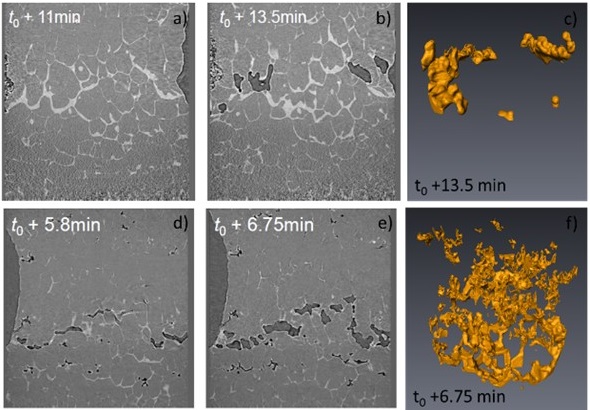

Semi-solid tensile experiment of an Al-Cu alloy in isothermal condition (a,b) with 3D rendering of porosity induced (c) and in solidification (d,e) with porosity rendering (f). The width of the sample is 1.4 mm.

We investigated the hot tearing behaviour of Al-Cu using in situ X-ray microtomography experiments at ESRF. We first performed isothermal tests and showed for the first time that liquid enrichment appears prior porosity nucleation. Then damage starts from the border and grows inside the enriched liquid zone. We also performed tensile tests during solidification after partial remelting: liquid enrichment is less important and several porosity nucleate in the bulk, grow and coalesce leading to a rapid rupture. This indicates clearly that hot tearing should be studied during solidification and not during isothermal tests.

High temperature deformation in steels

High temperature deformation of supermartensitic steels was studied in the framework of forming capacity of turbine blades, with a particular attention given to associated phase transformation. In optimal conditions of treatments, fine grained structures were successfully produced and constitutive laws describing the high temperature behavior were identified. Numerical simulations of forming steps were also carried out.

- R. Daudin, S. Terzi, P. Lhuissier, L. Salvo, and E. Boller, “Remelting and solidification of a 6082 Al alloy containing submicron yttria particles: 4D experimental study by in situ X-ray microtomography,” Mater. Des., 87 313–317 (2015).

- P. Lhuissier, M. Scheel, L. Salvo, M. Di Michiel, and J.J. Blandin, “Continuous characterization by X-ray microtomography of damage during high-temperature deformation of magnesium alloy,” Scr. Mater., 69 [1] 85–88 (2013).

- P. Lhuissier, A. Villanueva Fernandez, L. Salvo, and J.J. Blandin, “High Temperature Deformation and Associated 3D Characterisation of Damage in Magnesium Alloys,” Mater. Sci. Forum, 706-709 1128–1133 (2012).

- A.Volland, J. Ragani, Y. Liu, S. Gravier, M. Suéry, and J.J. Blandin, “Design of multi materials combining crystalline and amorphous metallic alloys,” J. Alloys Compd., 536 S143–S147 (2012).

- L. Salvo, P. Lhuissier, M. Scheel, S. Terzi, M. Di Michiel, E. Boller, J. a. Taylor, a. K. Dahle, et al., “3D in situ imaging of aluminium alloys during solidification,” Trans. Indian Inst. Met., 65 623–626 (2012).

- L. Salvo, M. DiMichiel, M. Scheel, P. Lhuissier, B. Mireux, and M. Suéry, “Ultra Fast In Situ X-Ray Micro-Tomography: Application to Solidification of Aluminium Alloys,” Mater. Sci. Forum, 706-709 1713–1718 (2012).

Chercheurs / Enseignants-chercheurs

PhD and post-docs

M. Alvarez,

T. Baumann,

P. Gravier

Collaborations

MATEIS : E. Maire, J. Adrien,

Saint-Gobain : E. Gouillart,

ALSTOM ;

U.C. Louvain (L. Delannay)