Liquid/solid and solid/solid activities

These include, on one hand, the study of relations between microstructures and solidification or heat treatment conditions, and on the other, the design and preparation by casting or sintering of new alloys with remarkable properties. The alloy grade is chosen by a coupled thermodynamic modelling approach and from key experiments.

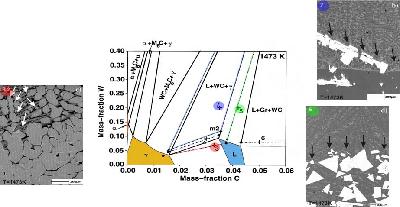

Composition of phases in equilibria corresponding to tie-lines and tie-triangles on the isothermal section at 1473 K of the C-Fe-W system.The arrows indicate a boundary limiting a liquid area. The coarse solid phases are located below this boundary (ANR ADRERA project, contact A. Antoni-Zdziobek) more

Gas/solid activities

These are aimed at understanding the phenomena of equilibrium and non-equilibrium vaporisation of condensed materials (powder mixes) and the optimisation of growth or etching processes starting from a gas phase.

Optimisation concerns both the development of the process and the choice of material (composition, structure) that is best suited to the application.

With regard to the preparation aspect, a facility for growing materials from the gas phase, including four CVD and ALD reactors, is used to produce ultra-thin films (of the order of a nm) and bulk materials (of the order of a mm)

- Our projects regarding ALD (Atomic Layer Deposition) of tantalum and copper nitrides and oxides, that are suitable at nanometric scale for microelectronics, are aimed at achieving process optimisation through a better understanding of the choice of precursor (based on mass spectrometry studies) and its reactivity with the surface.

- Considerable work has been done on high-temperature CVD preparation of thick monocrystalline or polycrystalline films of SiC, in collaboration with the LMGP laboratory, and this has expanded into the preparation of fast-growing (>100 mm/h) and high-temperature (>1700°C) epitaxiated or polycrystalline AlN material and polycrystalline Ti3SiC2 materials in partnership with ACERDE, a start-up created in 2007. The development of epitaxiated or monocrystalline AlN by HTCVD is extremely innovative, as the majority of work carried out at international level to obtain monocrystalline AlN has been focused on physical (PVT) techniques.

As far as characterisation is concerned, facilities are being developed at the laboratory for working at very small scales. In particular, Atomic Force Acoustic Microscopy for measuring local Young's moduli (depth probed ~20-50nm, submicronic lateral resolution) is currently being developed in collaboration with the PM group. Stiffness maps have already been obtained on Cu/SiO2 interconnection structures. A technique for measuring the adherence energy of thin films by combining electrical and mechanical measurements has also been developed and is currently being validated.

Nanocrystallisation processes - preparation of metallic glasses

Nanocrystallisation activities involving heat treatment of bulk metallic glasses (BMG) and mechanosynthesis using a synchrotron light beam are aimed at preparing non-equilibrium materials on account of their remarkable mechanical and chemical properties while contributing to the understanding and modelling of metastable phase formation phenomena. Correlations between mechanical properties and nanostructure are naturally investigated and determined in each case.

Other research areas of the group TOP

Event

Nitrides-carbides Workshop