The aim here is to improve the understanding and description of the effects of permanent or alternating magnetic fields, and/or their superimposition, on a fluid, electricity-conducting medium. The fluid domain may comprise free surfaces or multi-phase (inclusions, crystallites, bubbles), in the process of solidifying and/or subject to electrochemical reactions.

Examples are as follows:

- quantify effects connected with inflows and outflows of the electroconducting fluid in the magnetic field, in the liquid metal distribution devices or in circuits with sub-channels,

- develop processes or improve their performance, for example by controlling the interfaces and mass transfers at these interfaces, such as between a liquid metal and covering fluid or when solid ceramic surfaces are coated with metal,

- take advantage of the easier access to intense magnetic fields to improve knowledge relating to the description and control of thermoelectric and/or diffusion effects with the purpose to find promising applications such as optimising the electrodeposition and texturing of magnetic shape memory alloys,

- control inductive processes, which limit the production of secondary waste, on glasses, oxides and molten salts, materials that are connected in particular with the nuclear industry, applications being the vitrification of radioactive waste or the engineering of GEN-IV reactors,

- check the homogeneity, structure, quality of deposits and corrosion, in particular in covering the ITER tokamak.

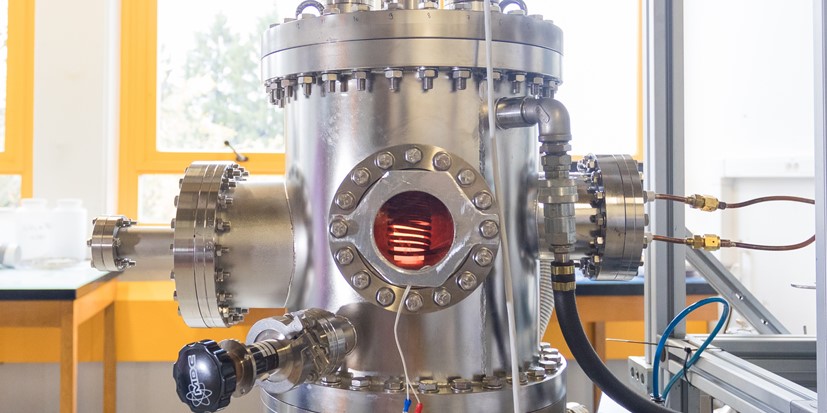

Liquid metal droplet located inside a uniform alternating magnetic field which frequency is fixed and intensity is varying, increasing from left to right. Left: the droplet is at rest, center: excited oscillations modes are regular, right: the intensity is such that the droplet is shaped generating satellites. |

Other themes

- Solidification in magnetic fields

- Electromagnetic processes

- Numerical modelling of coupled phenomena