Imaging is one of the leading characterization approach for the SIMaP lab. This is strongly related to the developments of TEM and X-ray tomography characterisation tools, which particularly developped at GPM2.

Advanced characterization by TEM mainly relies on the constant development of ACOM.

4D characterization during thermo-mechanical loading is accessible thanks to the developments in in situ micro and nano synchrotron tomography.

The Automated Crystal Orientation Mapping (ACOM) tool

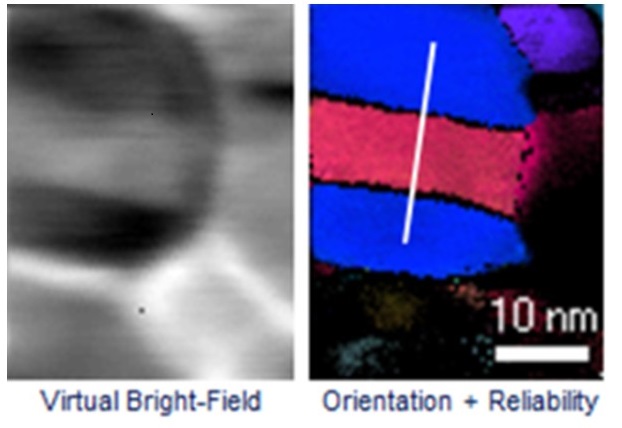

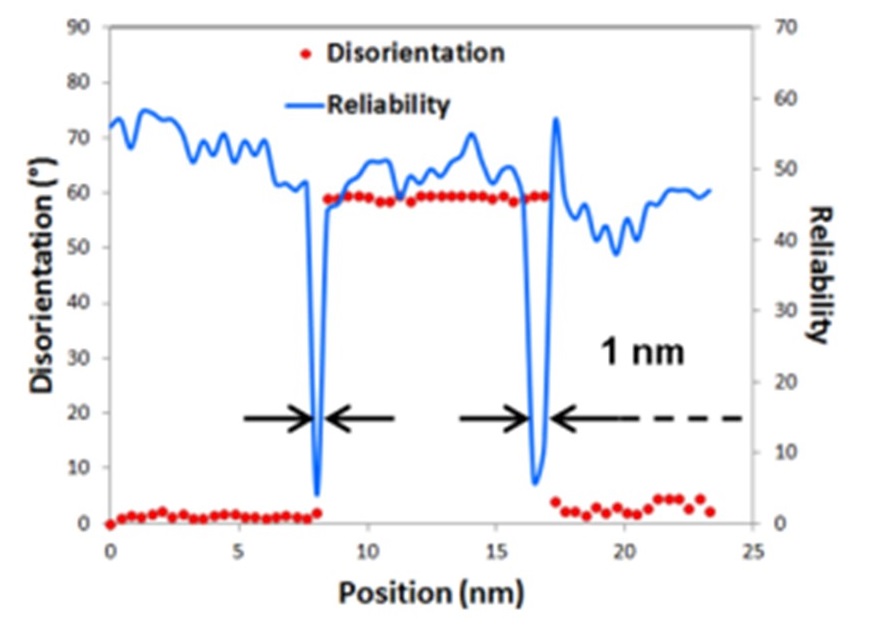

The spatial resolution is related to the detection limit of the boundaries between crystals. (JEOL 2100F)

The ACOM-TEM tool developed by E. Rauch (GPM2) and M. Véron (PM) and commercialized since 2009 by NanoMEGAS SPRL as ASTAR, provides phase and orientation maps at nanoscale, enables the identification of precipitates and distinguishes crystallized and amorphous components. It is based on the so-called template matching strategy that consists in comparing sets of pre-calculated diffraction patterns to the experimental signal either acquired in-situ with a dedicated camera or derived from high resolution (HRTEM) images through a Fourier transform. Around 80 ASTAR units are installed worldwide and more than 200 published works involve its usage. The spatial resolution accessible with the new JEOL 2100 FEG is 1 nm. Consequently, this TEM attachment is regularly exploited in the lab for structural characterisation at nanoscale. Around ten PhD works performed at SIMAP includes ACOM-TEM maps. The tool is constantly upgraded with new facilities.

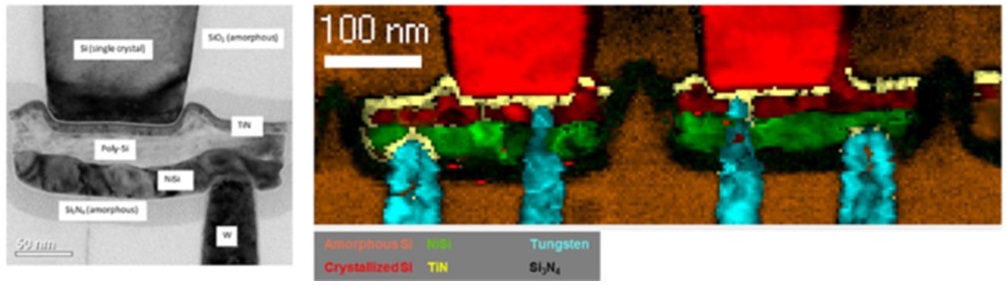

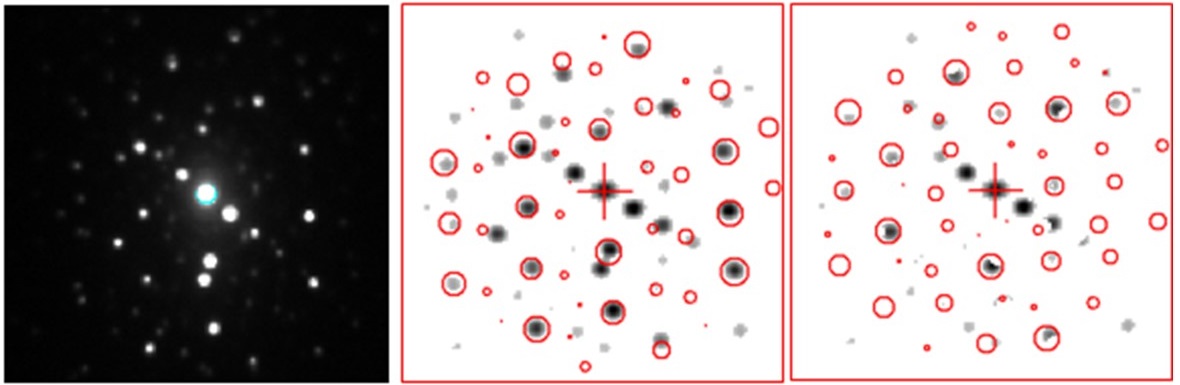

Amorphous phase detection

The template matching algorithm is efficient as long as a the material diffracting signature is known. In particular, the tool was adapted to amorphous phases. Indeed, the related diffraction patterns are composed of a main ring with a specific diameter that can be easily recognized. The figure below illustrates the capability of the tool to distinguish between crystallized and amorphous phases. This innovative technic is of particular interest for the microelectronics industry.

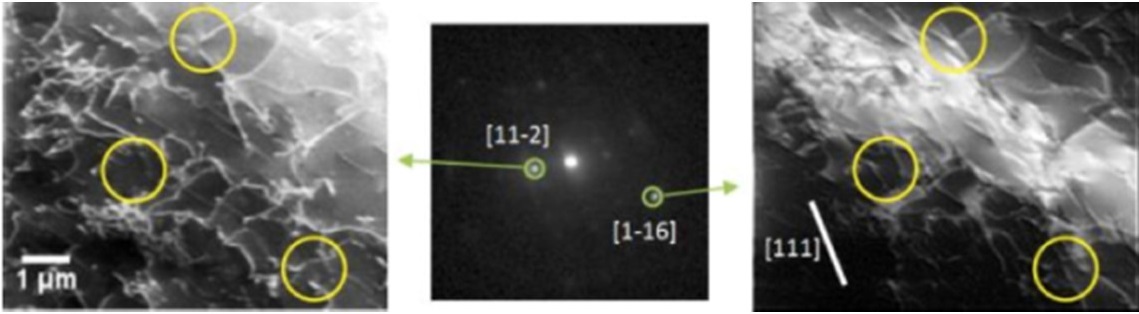

Virtual dark field images (VDF)

Deconvolution of superimposed diffraction patterns

Successive template matching solutions with intermediate pattern subtraction. (Microscopy and Microanalysis (21/S3) 1243–1244)

For grain sizes lower than the thin foil thickness, the pattern is composed of superimposed reflection networks, each being related to a given grain crossed by the beam. To distinguish them, it has been proposed to subtract the spots related to first dominant crystal and to re-index the remaining pattern. The resulting algorithm is apply successively and was shown to be able to distinguish 3 to 5 grains in the sample thickness.

In situ X-ray nano-tomography thermo-mechanical tests

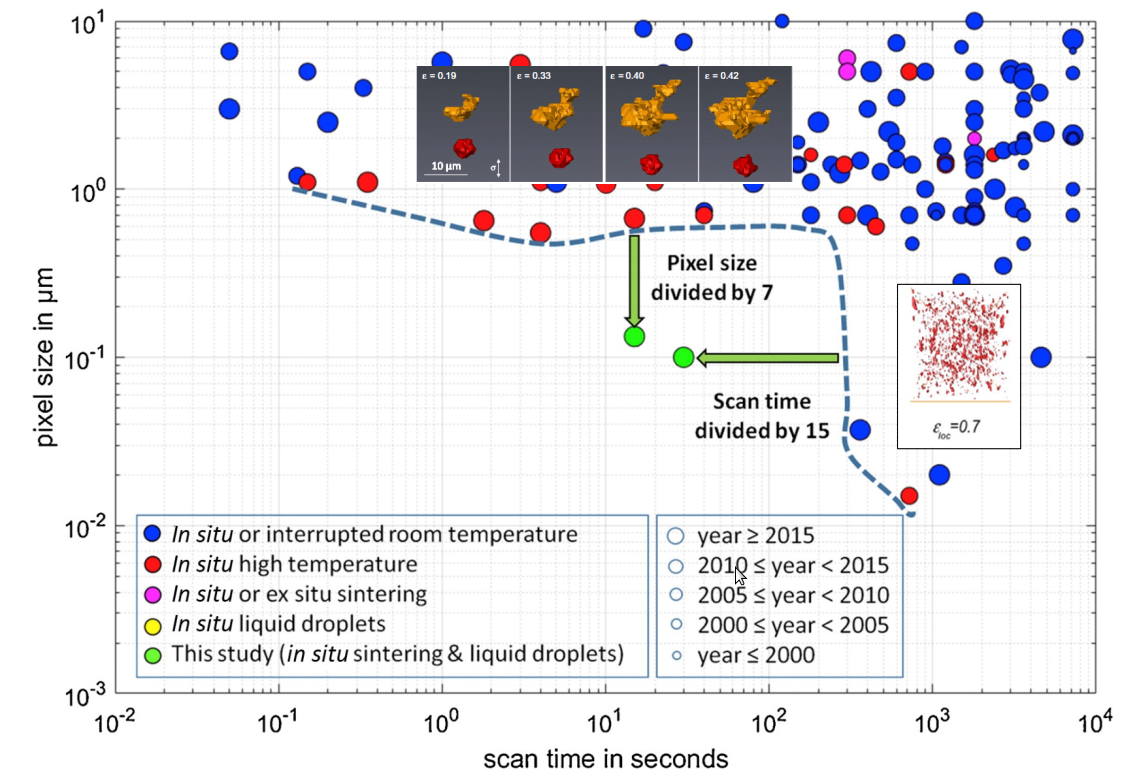

Combination of spatial resolution and acquisition time required to

perform in situ nano-tomography tests [Villanova et al., Materials Today (2017)]

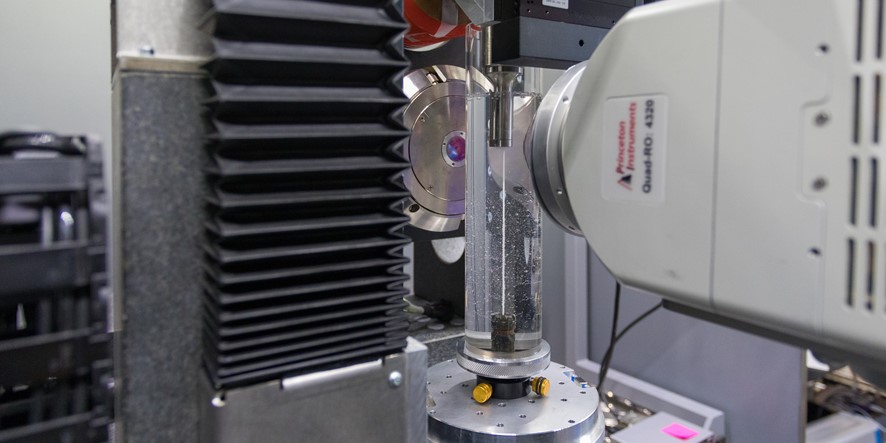

In situ nano-tomography tests are achieved thanks to a unique combination of high resolution (35-500nm) and short acquisition time (few seconds). Dedicated furnace and tensile system allow to investigate pores nucleation and growth during high temperature tensile tests of light alloys.

In situ ultra-fast X-ray micro-tomography

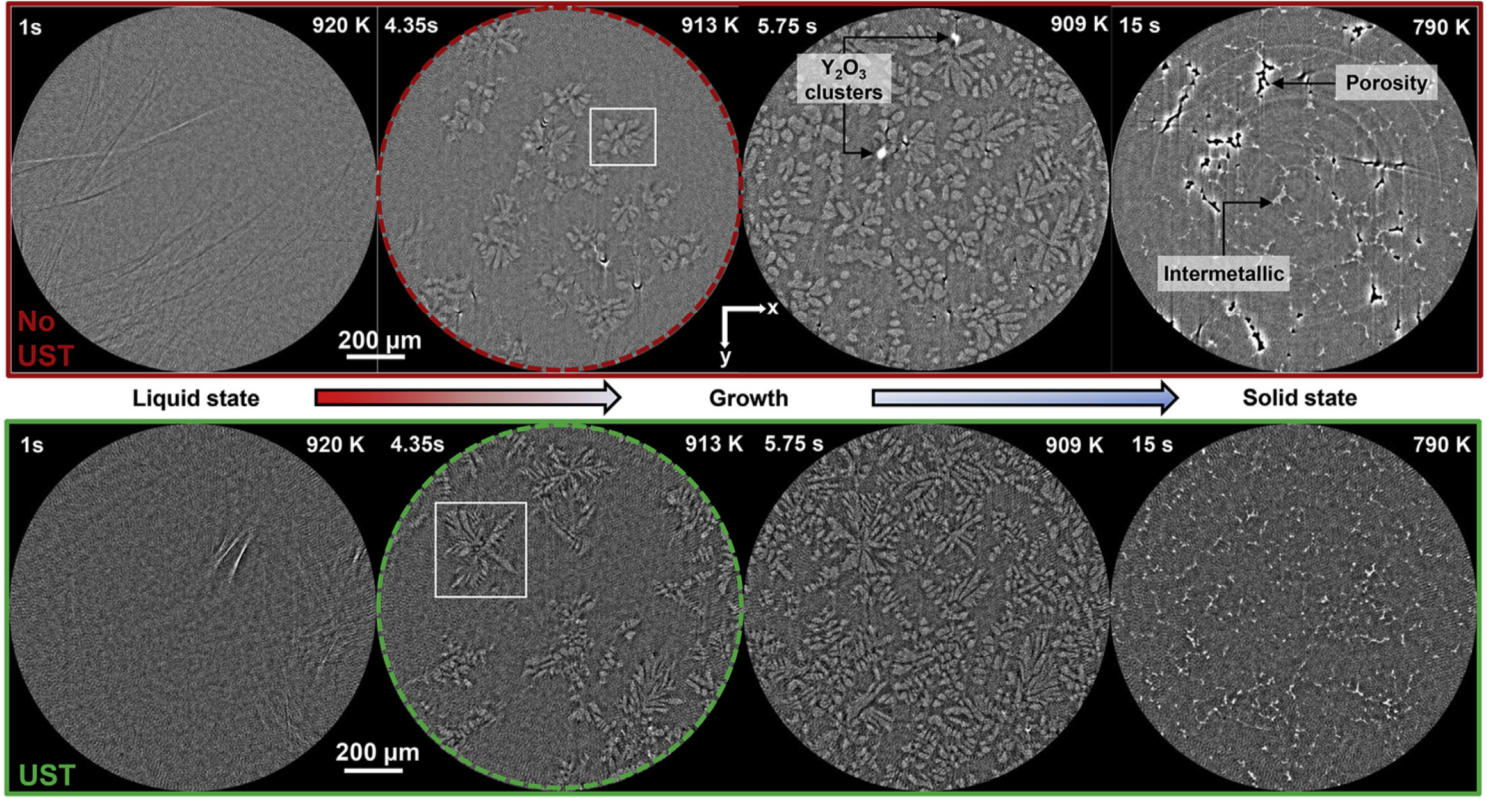

Effects of ultra-sound stiring on dendrites morphology during the solidification of aluminium alloy reinforced by nano-particles [Daudin et al., Acta Mater. (2017)]

Ultra-fast in situ micro-tomography combine a micrometric spacial resolution and a sub-second temporal resolution. It allows to investigate time dependant system such as solidification and high temperature mechanical tests. Dedicated samples environments are developped to match the acquisition constrains.

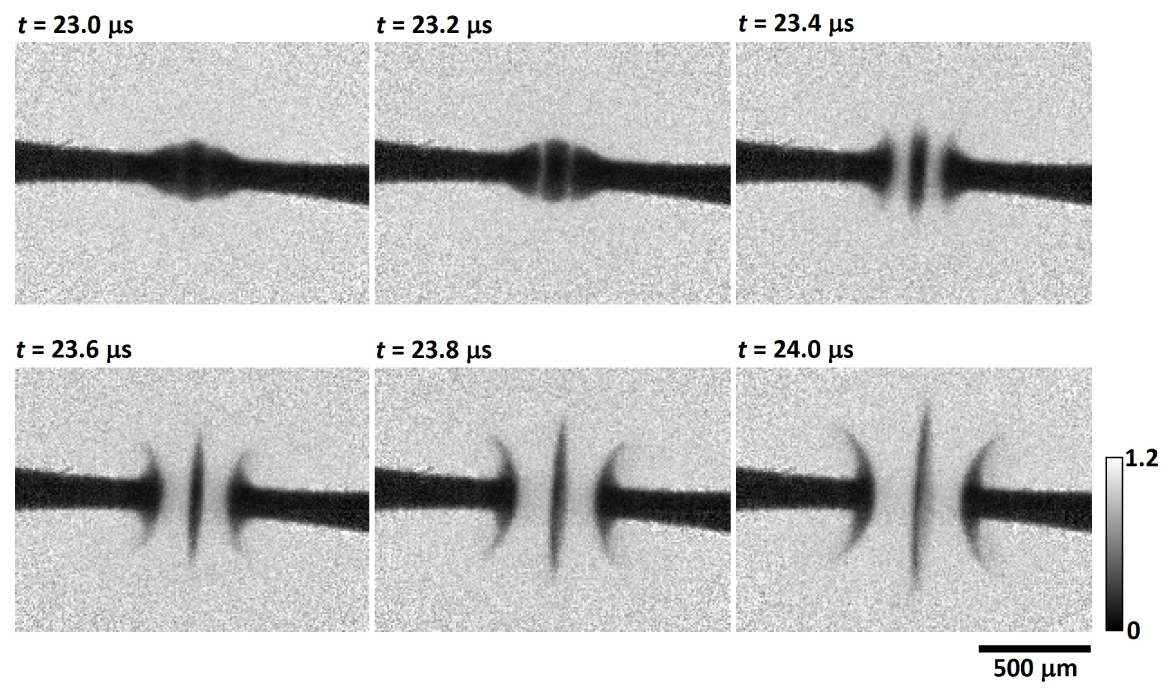

MHz frame-rate X-ray radiography

X-ray radiographs of electric arc ignition during fuse operation

[Olbinado et al., Optics Express (2017)]

MHz frame-rate radiographs using hard X-rays phase contrast allows to investigate highly dynamic phenomena such as electric arc ignition.

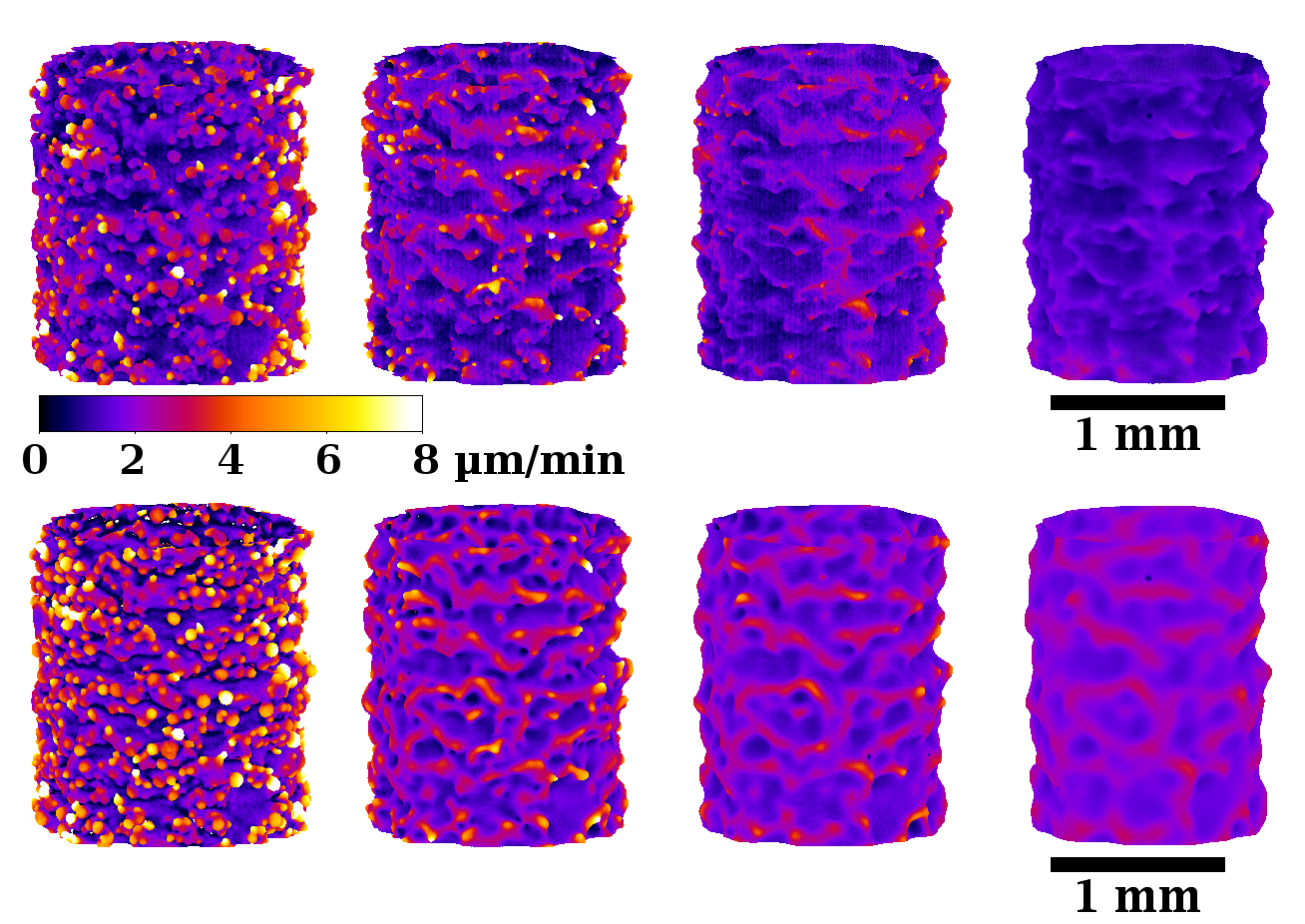

Laboratory X-ray microtomography

Evolution of EBM TA6V strut surface during chemical etching. Comparision of local etching velocity between experiment (top) and model (bottom) [Lhuissier et al., Mater. & Design (2016)]

Ex-situ or in situ interrupted experiments can be conducted on laboratory equipements. When acquisition time is not a major constrain, the same sample can be imaged at various stages of the process (mechanical loading, thermal treatment, etching...).

Chercheurs / Enseignants-chercheurs

PhD and post-docs

Thibaut DESSOLIER (2018)

Pauline GRAVIER (2019)

Richie KUMAR (2019)

Habib MURTAZA (2021)

Dawei PENG (2022)

Aatreya VENKATESH (2022)

Alexia VALERY (2017)

Collaborations

Deakin U. ,

Hungarian Academy of Sciences,

IIT Pisa,

Cambridge U.,

U. Federal de São Carlo,

ST microelectronics