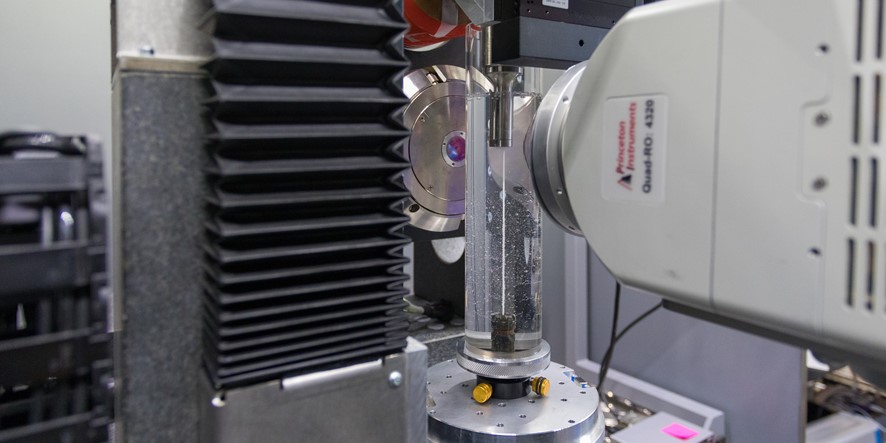

>Research activities and developments on X-ray tomography are closely linked to the scientific questions tackled at SIMaP/GPM2. Recent developments together with ESRF are mainly concerned with the reduction of the acquisition time in order to obtain a 3D image with a spatial resolution of about one micrometer in the order of a second. In ongoing and future efforts, we aim at a fine spatial resolution (50 nanometre) together with less than a few tens of seconds during thermal loading. In parallel, developments are carried on the lab tomograph for quasi-static conditions.

Objectives

Fast tomography allows 4D materials to be imaged during thermo-mechanical loadings. The aims is to develop, in collaboration with ESRF this characterization tool, and to make it fully compatible with high temperature tests for which time is a challenging issue due to thermally activated phenomena.

The development of fast tomography results in major scientific achievements in several scientific domains such as solidification defects kinetics and high temperature damage evolution.

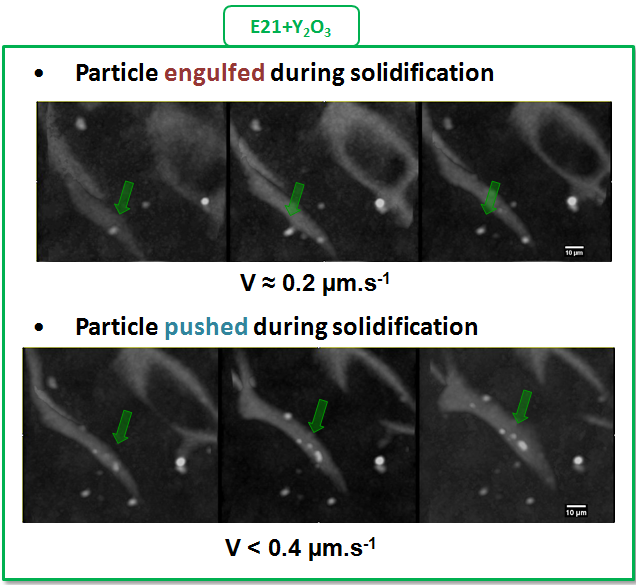

Nano-composites solidification and ultrasonic stirring

In situ observation of a semi solid E21 Magnesium alloy reinforced by Y2O3 particles. Depending on the liquid interface velocity, particles are either engulfed or pushed by the liquid interface.

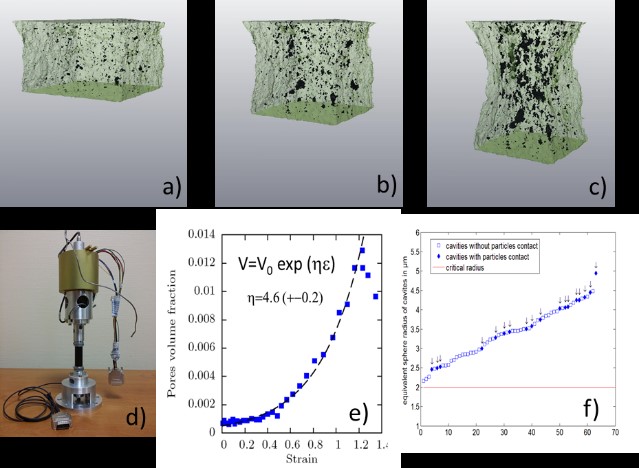

High temperature damage evolution

High temperature deformation of a magnesium alloy AZ31. a-c : 3D rendering of the damage for several macroscopic strains. d : High temperature tensile device. e : evolution of pores volume fraction as a function of the macroscopic strain. f: interaction between porosities and intermetallics.

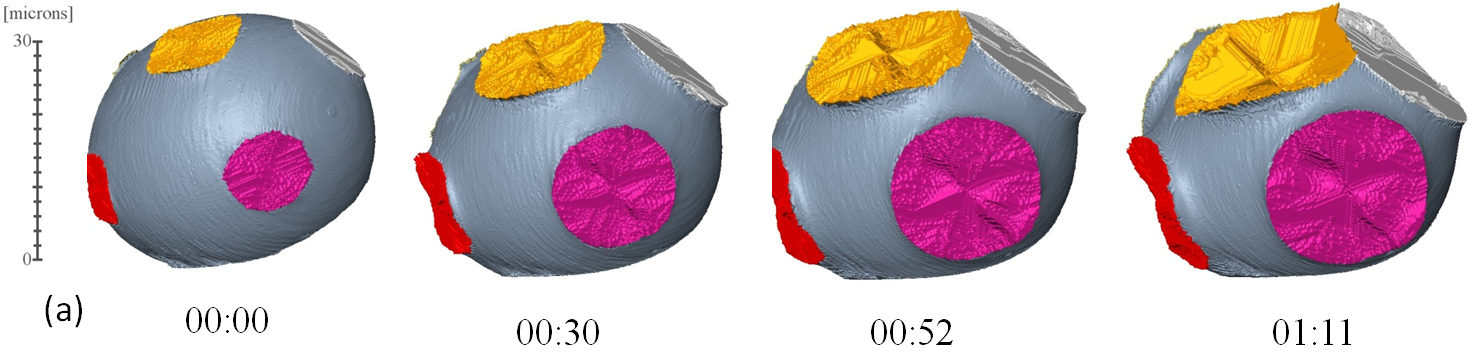

Sintering at the particle length scale

Isothermal sintering at 670°C of glass beads. 3D rendering of neck radius as a function of time.

Sheet folding

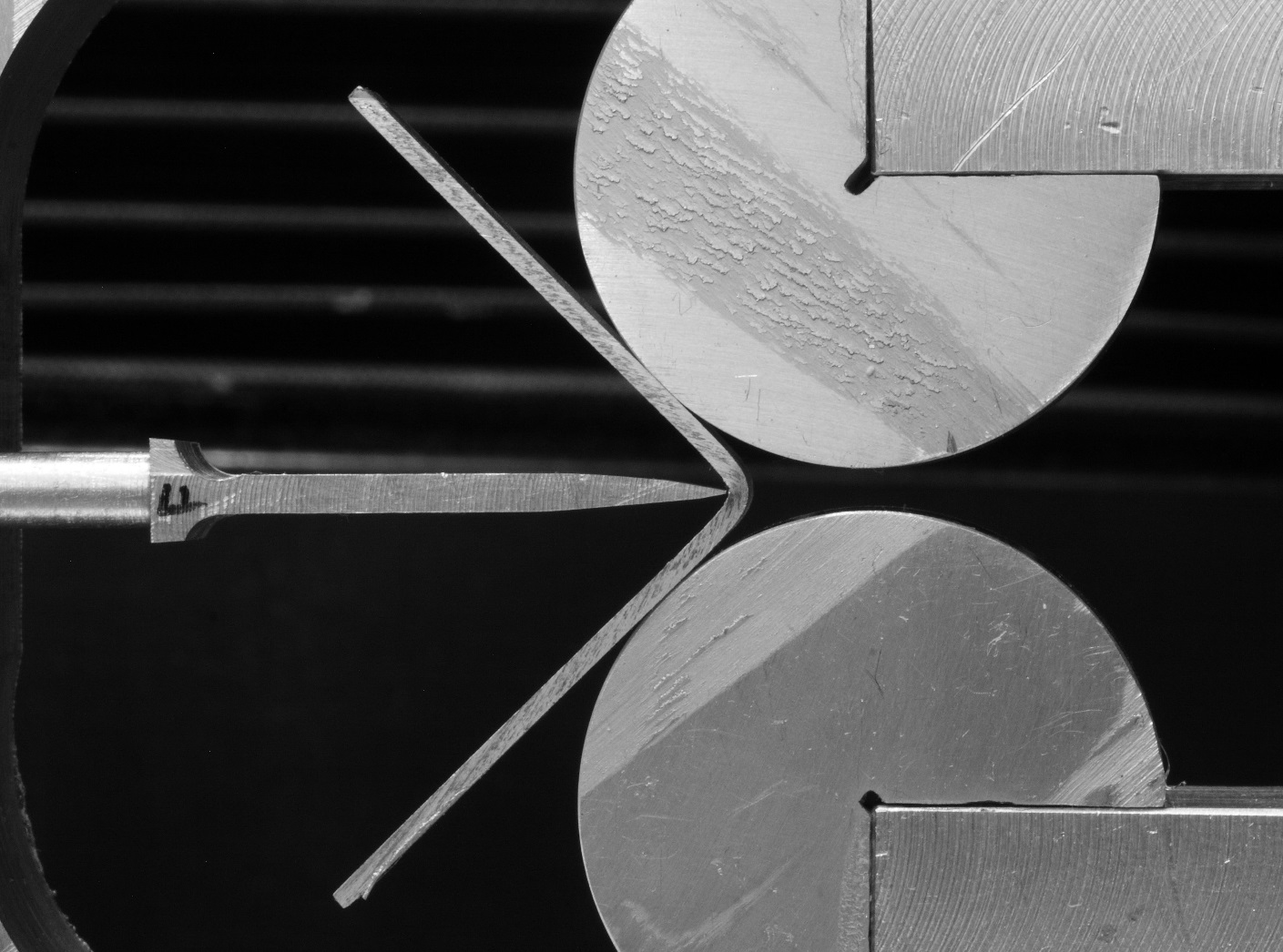

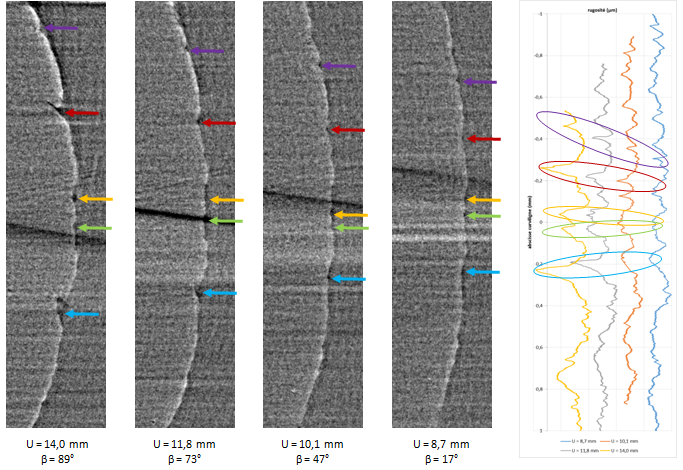

Left: folding device developed for in situ tests. Right : Example of tracking of cracks and roughness in the plane submitted to plane stress.

We investigate the ability to characterise in situ aluminium sheets folding in collaboration with Constellium. A dedicated loading device and an acquisition procedure have been developed in order to perform such tests on a lab tomograph. These preliminary experiments demonstrate our ability to bring new information on the relations between localization band, voids, and roughness.

- R. Daudin, S. Terzi, P. Lhuissier, L. Salvo, and E. Boller, “Remelting and solidification of a 6082 Al alloy containing submicron yttria particles: 4D experimental study by in situ X-ray microtomography,” Mater. Des., 87 313–317 (2015).

- D. Bouttes, O. Lambert, C. Claireaux, W. Woelffel, D. Dalmas, E. Gouillart, P. Lhuissier, L. Salvo, et al., “Hydrodynamic coarsening in phase-separated silicate melts,” Acta Mater., 92 233–242 (2015).

- P. Lhuissier, M. Scheel, L. Salvo, M. Di Michiel, and J.J. Blandin, “Continuous characterization by X-ray microtomography of damage during high-temperature deformation of magnesium alloy,” Scr. Mater., 69 [1] 85–88 (2013).

- Z. Yan, O. Guillon, C.L. Martin, S. Wang, C.-S. Lee, and D. Bouvard, “In-situ synchrotron x-ray transmission microscopy of the sintering of multilayers,” Appl. Phys. Lett., 102 223107 (2013).

- D. Tolnai, P. Townsend, G. Requena, L. Salvo, J. Lendvai, and H.P. Degischer, “In situ synchrotron tomographic investigation of the solidification of an AlMg4.7Si8 alloy,” Acta Mater., 60 [6-7] 2568–2577 (2012).

- L. Salvo, M. DiMichiel, M. Scheel, P. Lhuissier, B. Mireux, and M. Suéry, “Ultra Fast In Situ X-Ray Micro-Tomography: Application to Solidification of Aluminium Alloys,” Mater. Sci. Forum, 706-709 1713–1718 (2012).

Research Staff

PhD and post-docs

M. Alvarez,

R. Kumar

Collaborations

MATEIS : E. Maire, J. Adrien,

SVI : E. Gouillart,

LMT : S. Roux, H. Leclerc,

GIPSA : V. Fristot, D. Houzet,

LRM : S. Zabler,

ICMB : D. Bernard