OLD-PAGE Roughly 15 permanent researchers and 15 PhD students, visitors or trainees are part of the PM group. Activities focus on the physical metallurgy of alloys. We aim to relate several structural scales and the complexity of atomic organization to the properties of the alloy material. These cover a wide range and include mechanical properties such as plasticity and failure, but also magnetic, electric or thermal properties, all of which are influenced by microstructure. We study industrial alloys, complex metallic phases and nanostructured systems (thin films, multilayers, etc.). More recently, the link between microstructure/nanostructure and properties has been extended in our studies to architectures (for instance sandwich structures) and a new research topic covering the relationship between microstructure, architecture and mechanical properties has emerged, in fruitful collaboration with the GPM2 group.

Objectives

- Understanding the relation between microstructures and properties

- Understanding and controlling the genesis of micro- and nanostructures

- Quantitative characterization of defects and local mechanical properties

Fields of application

- Materials for structural applications and structure lightening

- Nuclear materials

- Local quantitative measurement for micro- and nanotechnologies

Microstructure and phase transformation

| - precipitation kinetics: experiments and modelling - relation between precipitation, microstructure and properties - phase transformation and interface migration: recrystallization, massive transformation, etc. - phase transformation and plasticity (TRIP/TWIP steels)- plasticity in micro/nanostructured systems |

|

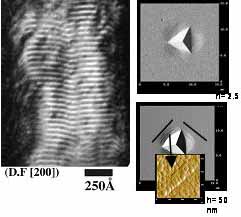

Nanostructures and nano-objects

| - impact of size reduction on plasticity and phase transformation - metallic thin film deposited on patterned Si substrates - interconnection for microelectronic applications: nanostructure characterization, properties, reliability - ordering and magnetism in self-organized nanoparticles |

|

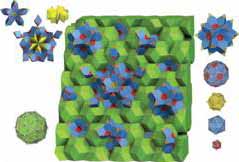

Complex metallic alloys

The study of the structure of complex metallic alloys is related to the fundamental question of the stabilization mechanisms of aperiodic crystals. The discovery of the CdYb icosahedral phase was a breakthrough in this field since it led to a detailed understanding of its atomic structure. It has been possible to show that the atomic structure of this quasicrystal can be described as a packing of icosahedral clusters presenting a well-defined chemical order. Further steps are now to understand the nature of disorder and to investigate structures with a lesser degree of complexity but with the same kind of local order. This work is part of a large long-term international collaboration programme within Europe (NoE CMA, European Consortium C-Mac) and beyond (in particular with Japan).| - complex metallic alloys: structure, defects, properties - Laves phases (MgZn2 structure type): atomic decoration, cluster analysis - atomic structure, phonons and phasons in quasicrystalline - composite alloys with high volume fraction of CMA phases |

|

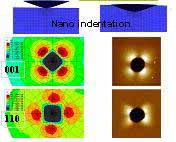

Microstructures - architectures and mechanical properties

The relation between microstructures and mechanics is a relevant issue for the applications of numerous materials. This question involves characterizing and modelling mechanical behaviour at different scales and also dealing with the heterogeneity of the material. Heterogeneity may be due to grain boundaries, dislocation walls or interfaces due to the formation of a second phase by solid state phase transformation, or to more heterogeneous interfaces such as those obtained by welding. In the PM group, activity focusses mostly on the size effect (for instance the mechanical behaviour of thin films) and the relation between microstructure and damage in steels or aluminium alloys. However it is also closely connected with the SIR group's activity on interface mechanics and with the GPM2 group's work on the design and architecture of materials.| - mechanical properties and design (collaboration with GPM2 group) - numerical simulation of mechanical behaviour of thin films - microstructure and mechanical resistance of welding in Al alloys - modelling of interfaces (adhesion, delamination..) (collaboration with SIR group) |

|

Experimental techniques

We use mainly microscopy techniques (AFM, SEM, TEM) and X-ray scattering on laboratory equipment. Diffraction studies are complemented by X-ray or neutron experiments carried out at the ESRF synchrotron (in particular on the D2AM beamline, for which 4 members of the group are also local contacts) or the ILL neutron reactor. In parallel, and for each length scale, appropriate models are developed, both analytically and numerically. The activities of the PM group can be separated into several areas as listed below and illustrated by the titles of some studies currently in progress.

The group is also strongly involved in instrumentation, both for elaboration and characterization

- Molecular Beam Epitaxy chamber and associated characterization equipment (XPS/Auger, LEED, RHEED)

- Nano-indenter

- AFM-MFM

- X-ray diffraction/scattering (rotating anode and ESRF beamline)

- Neutron scattering

- Transmission Electron Microscopy (imaging and spectroscopy)

Organisation

- M. Verdier (Leader)

- F. De Geuser (Co-Leader)

- V. Chapays

(Administration)

(04 76 82 65 18)

Research areas

- Microstructure and phase transformation

- Nanostructures and nano-objects

- Complex metallic alloys

- Microstructures-architectures and mechanical properties