Damage mechanism during cavitation erosion

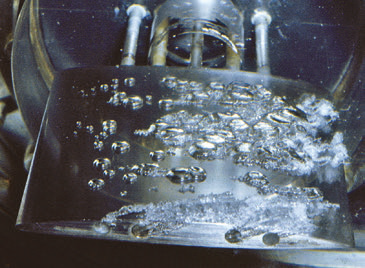

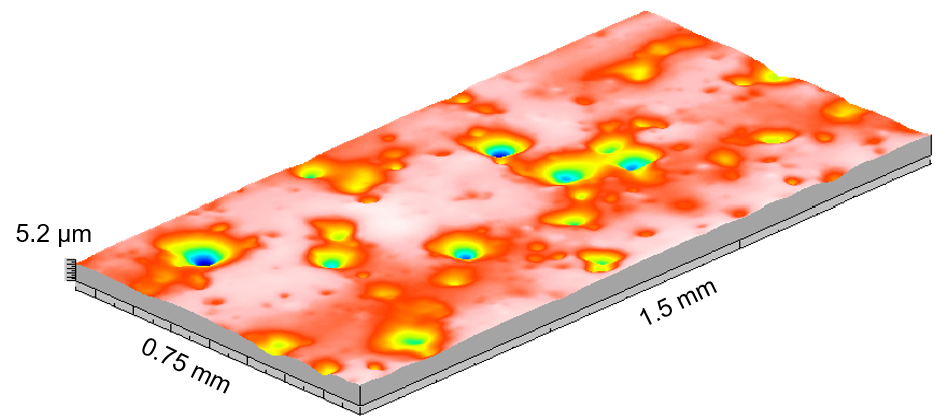

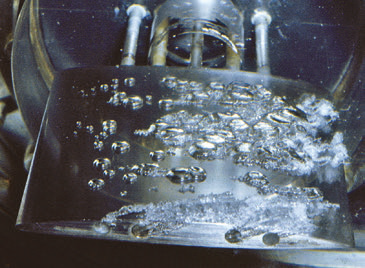

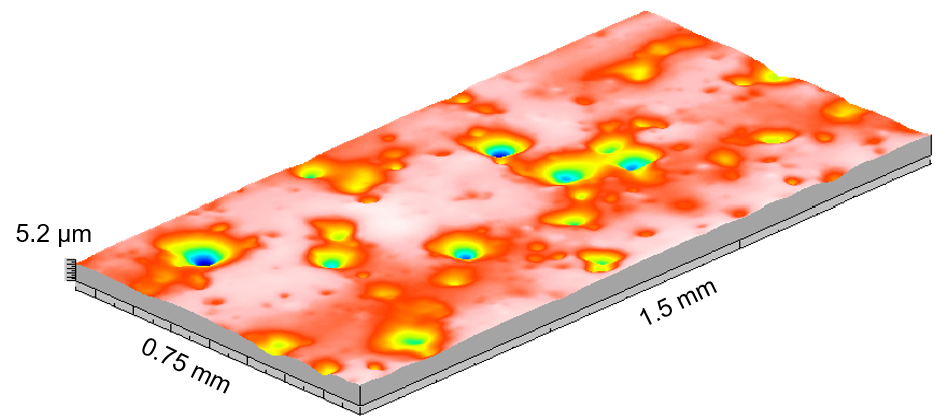

In fluid mechanics, cavitation describes the growth of bubbles within a liquid due to a drop of pressure as shown below (left) on the upper side of an hydrofoil tested at Laboratoire des Ecoulements Géophysiques et Industriels (LEGI). Hydrodynamic cavitation is a main concern for many industrial applications such as pumps, hydraulic turbines, ship propellers, fuel injectors or valves since it may induce damage on the material. Cavitation damage starts with an incubation stage where the surface of the material exposed to cavitation shows isolated pits (see figure below on the right). Each pit corresponds to the collapse of individual bubbles. The bubble collapse (see slow motion movie below) is a violent (few GigaPascals) and highly dynamic (a few microseconds) process which induces plasticity and damage on the material. Modelling cavitation damage requires to accurately account for the fluid/structure interactions and to take care of dynamic effects such as inertia and shock waves.

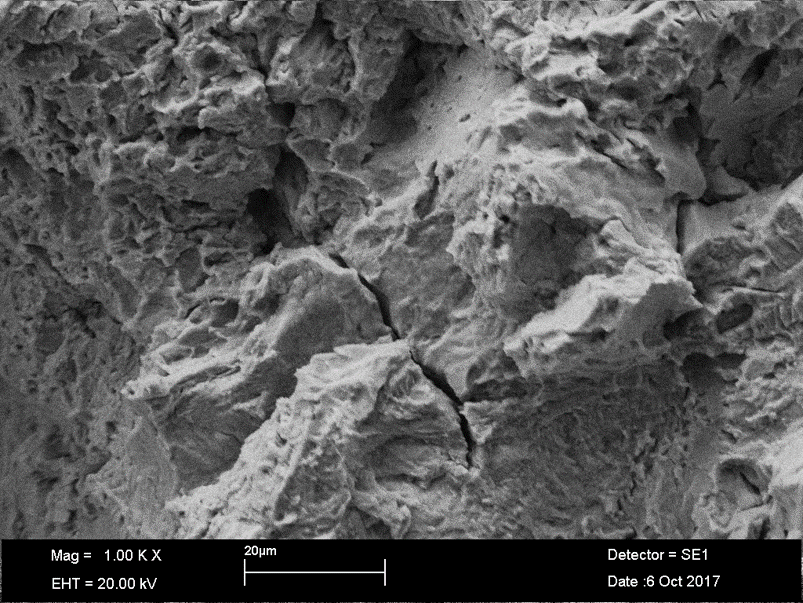

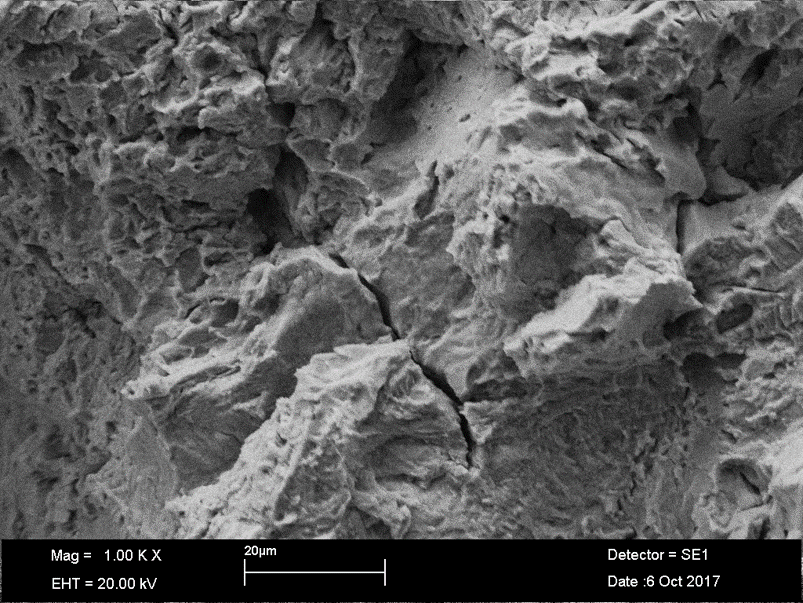

SIMaP and LEGI have been closely collaborating on cavitation erosion modeling since 2012. The problem has been first adressed using an inverse Finite Element method to estimate the flow aggressiveness (Ph.D. S. Roy 2015). The modeling of plasticity induced by a single bubble collapse has then been performed using a fluid/structure interaction scheme based on a coupling between a Finite Element code and a Computational Fluid Dynamics solver (Ph.D. Y. Paquette 2017). The coupling scheme has been recently improved using a compressible fluid solver (Ph.D. P. Sarkar 2019). Finally, the bubble collapse and the plasticity induced in the solid have been simultaneously simulated using a 2D axisymmetric Smoothed Particle Hydrodynamics model as shown in the animation below (Ph.D. S. Joshi 2018). The ongoing work will now focus on the development of a dynamic model of crack initiation and propagation which could predict the damage observed during cavitation erosion (see figure below on the right).

SIMaP and LEGI have been closely collaborating on cavitation erosion modeling since 2012. The problem has been first adressed using an inverse Finite Element method to estimate the flow aggressiveness (Ph.D. S. Roy 2015). The modeling of plasticity induced by a single bubble collapse has then been performed using a fluid/structure interaction scheme based on a coupling between a Finite Element code and a Computational Fluid Dynamics solver (Ph.D. Y. Paquette 2017). The coupling scheme has been recently improved using a compressible fluid solver (Ph.D. P. Sarkar 2019). Finally, the bubble collapse and the plasticity induced in the solid have been simultaneously simulated using a 2D axisymmetric Smoothed Particle Hydrodynamics model as shown in the animation below (Ph.D. S. Joshi 2018). The ongoing work will now focus on the development of a dynamic model of crack initiation and propagation which could predict the damage observed during cavitation erosion (see figure below on the right).

Plasticity in metallic glasses

The amorphous structure of metallic glasses is at the origin of their peculiar mechanical properties. The most impressive are for instance their very high yield strengths (from 1500 to as high as 3000 MPa) as well as their very large elastic deformation ability (up to 2%). Their are in general however poorly ductile at room temperature, at least in tension. One of the major challenge in the scientific community is to understand the relationship between their structure and how this latter evolve during their deformation, both in the elastic and in the plastic regime as well as how they fail. The mechanical responses of these materials depend obviously on their compositions but more interestingly also on less intuitive characteristics such as their sizes or their deformation histories, even in the elastic regime.

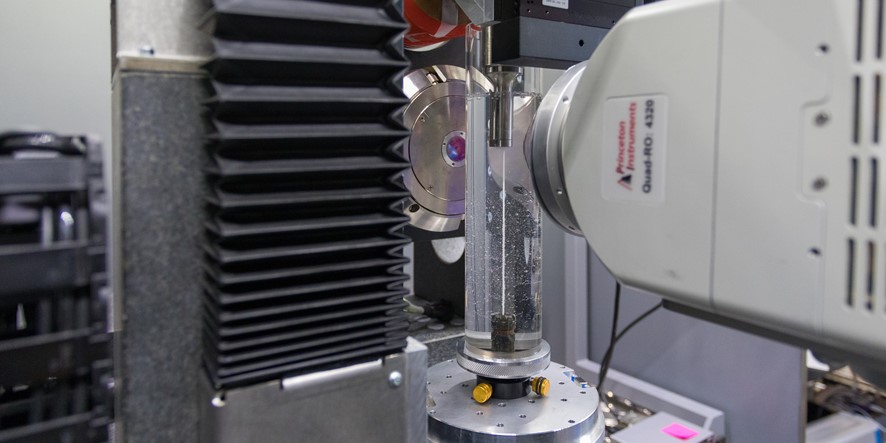

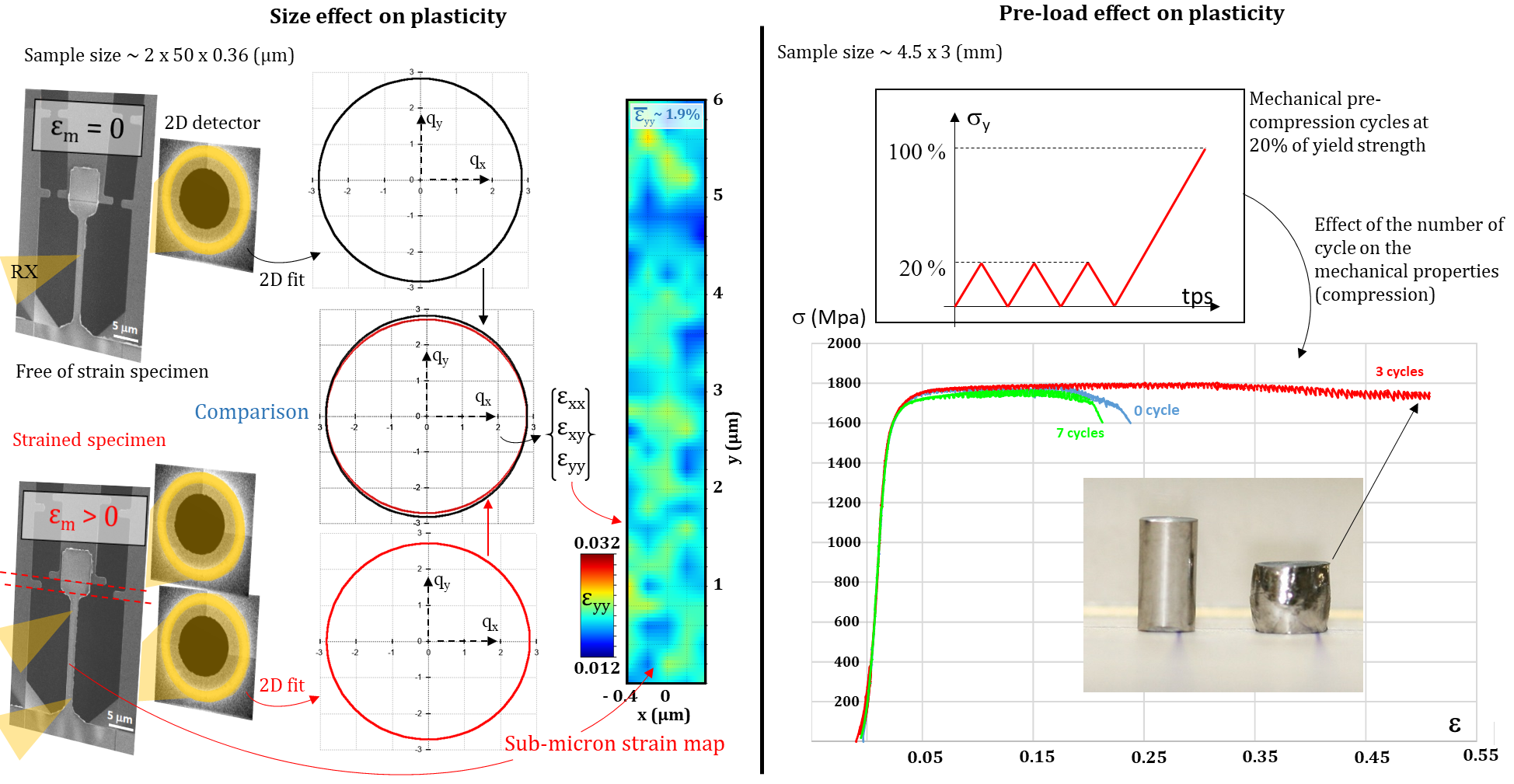

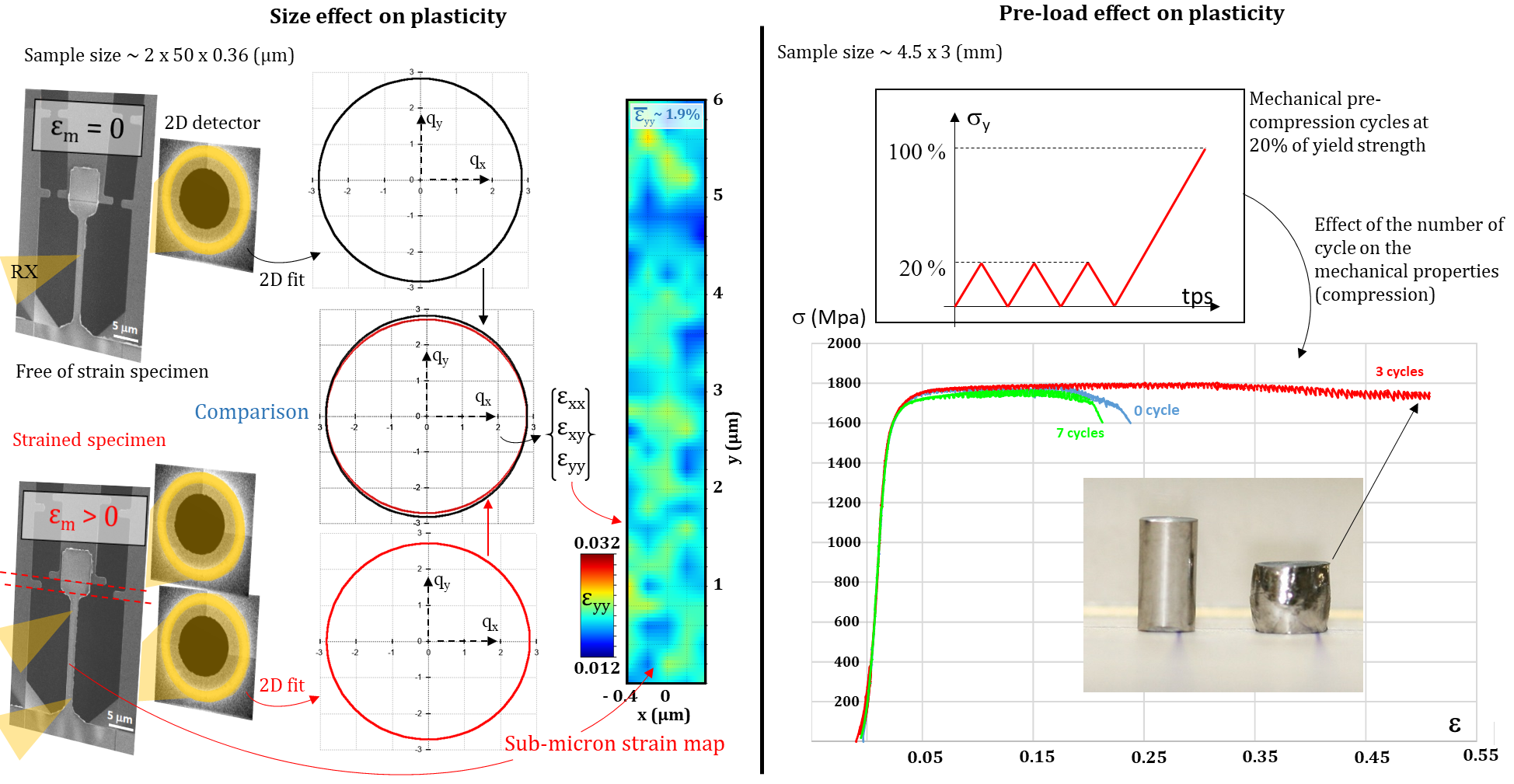

Left: Thin metallic ZrNi amorphous thin film specimens were produced by PVD in collaboration with the IMAP Laboratory in Belgium (Université Catholique de Louvain) and tested in tension thanks to the "micro-machine" technology. Surprisingly, specimens of thicknesses below 500 nm were found to exhibit higher yield strength as well as giant ductility (up to 14 % !) inducing the idea of "the smaller, the better" (Matteo Ghidelli thesis, Acta. Mat. Paper). To go further in the understanding of such mechanical properties, preliminary tests using a nano-focused X-ray beam (ESRF-ID01 beamline) were performed in order to probe and map the local deformation at a sub-micron scale and see how it correlates with the macroscopique deformation.

Right: In this case, 3 mm diameter rods of a Zr-based bulk metallic glasses were processed by arc-melting followed by suction casting and room temperature compression tests with differents pre-loading stages (0, 3 or 7 load cycles at 20 % of the yield strength). The results show that structural modifications, called "rejuvenation" in the litterature, and therefore different macroscopic deformation capacities can be induced by a few small pre-sollicitations in the elastic regime. The very nature of these features remains however still unknown.

Left: Thin metallic ZrNi amorphous thin film specimens were produced by PVD in collaboration with the IMAP Laboratory in Belgium (Université Catholique de Louvain) and tested in tension thanks to the "micro-machine" technology. Surprisingly, specimens of thicknesses below 500 nm were found to exhibit higher yield strength as well as giant ductility (up to 14 % !) inducing the idea of "the smaller, the better" (Matteo Ghidelli thesis, Acta. Mat. Paper). To go further in the understanding of such mechanical properties, preliminary tests using a nano-focused X-ray beam (ESRF-ID01 beamline) were performed in order to probe and map the local deformation at a sub-micron scale and see how it correlates with the macroscopique deformation.

Right: In this case, 3 mm diameter rods of a Zr-based bulk metallic glasses were processed by arc-melting followed by suction casting and room temperature compression tests with differents pre-loading stages (0, 3 or 7 load cycles at 20 % of the yield strength). The results show that structural modifications, called "rejuvenation" in the litterature, and therefore different macroscopic deformation capacities can be induced by a few small pre-sollicitations in the elastic regime. The very nature of these features remains however still unknown.

High temperature deformation

The work performed on high temperature deformation of metals (in particular in superplastic conditions) and composites is mainly experimental. Various kind of metals (aluminium alloys, magnesium alloys, steels, metallic glasses, composites, etc.) are investigated. Research focuses in the main deformation mechanisms, in the study of damage nucleation and growth as well as in the thermal stability of the materials.

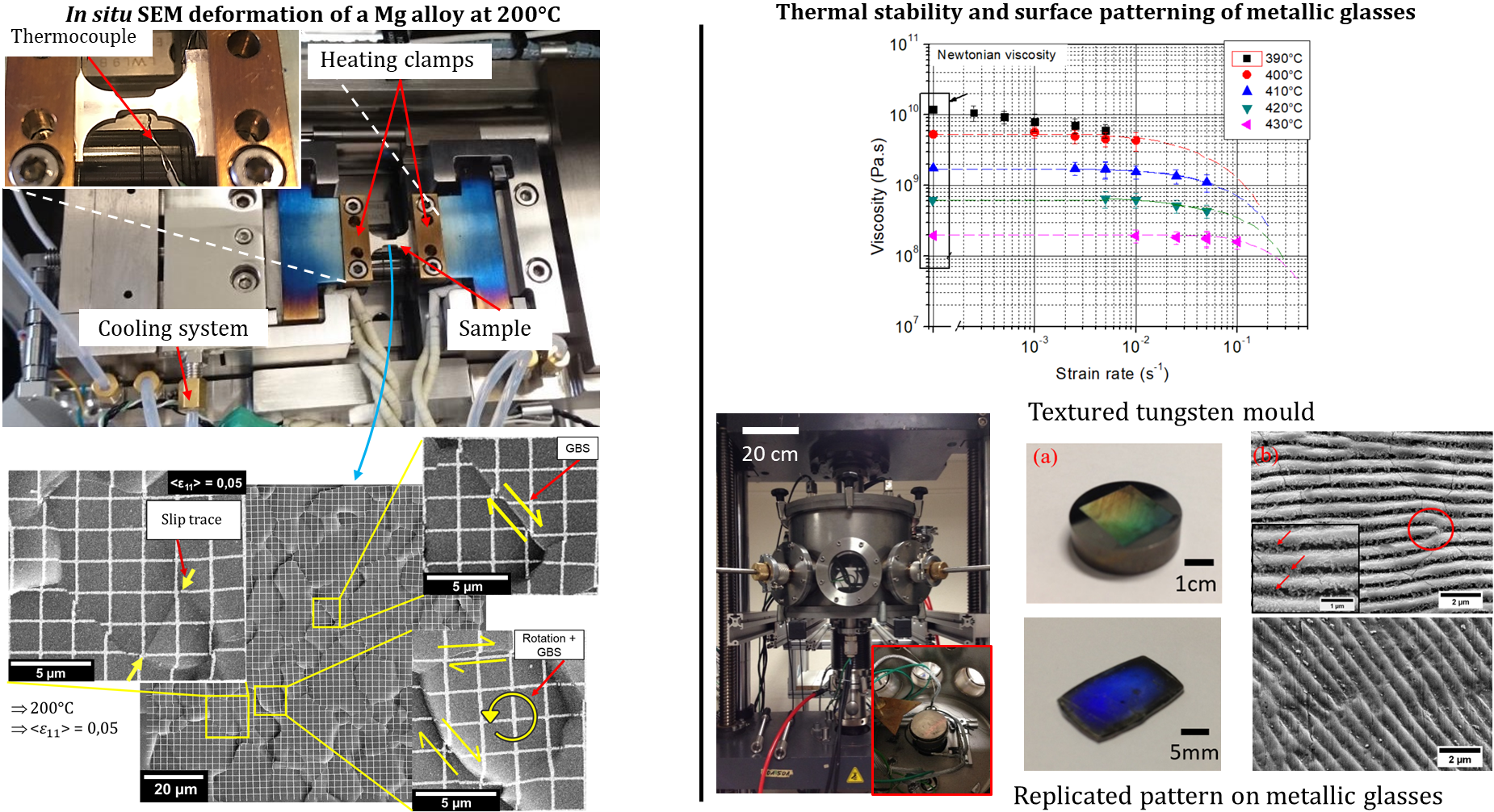

Left: A methodology to perform in situ high temperature tensile tests of Mg-alloys within a SEM with a high degree of mechanical and temperature control has been developed. The fact that Mg might vaporize under vacuum requires technical challenges to be overcome if one aims at conducting tests without damaging the microscope. Such a methodology allows to shed light on the link between the development of local strain heterogeneities and the occurrence of fundamental deformation mechanisms (Thibault Dessolier thesis).

Right: While metallic glasses are poorly ductile at room temperature, their deformation with increasing temperature becomes more and more homogeneous. As for oxyde glasses, above their glass transition temperature (Tg), they can undergo very large strain without detrimental effect on their amorphous structure. We use this property to functionnalize metallic glasses surfaces. Compression tests with strain-rate jumps at different temperatures around Tg allows the Newtonian viscosity of the desired composition to be determined (see top Figure). Subsequently, compression experiments under vacuum at high temperature can be performed in the adapted temperature-stress-strain rate condition to replicate fine patterns at the surface of metallic glass (Paul Hervier thesis). Such functionnalization can provide enhanced surface properties in many domains (wear resistance, wettability, optical response, corrosion-resistance, biocompatibility, etc.)

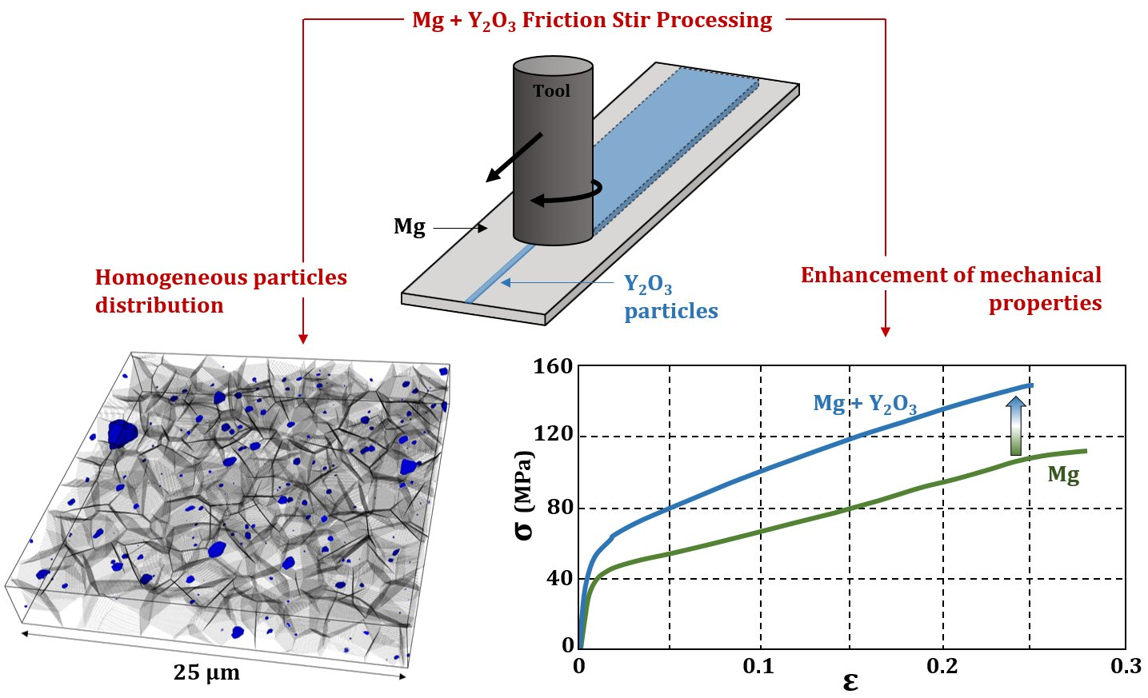

Enhanced mechanical properties through nano-particles reinforcements

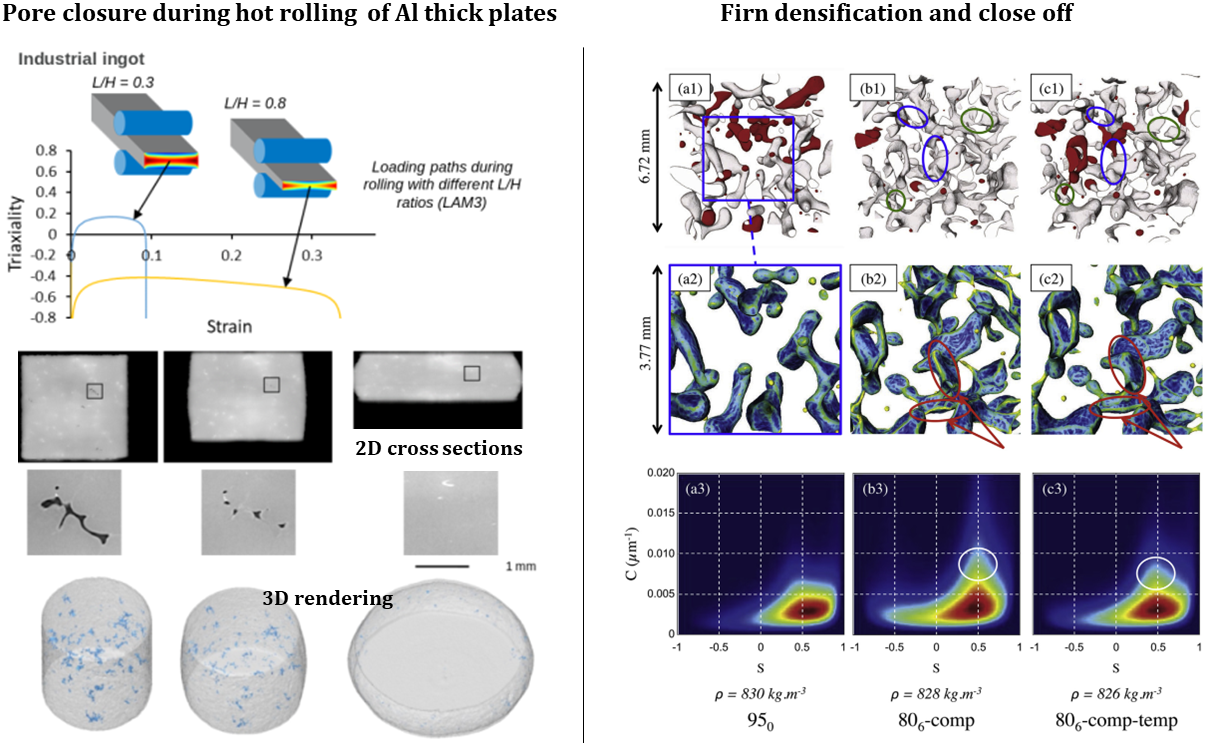

In situ visualization of morphological changes during deformation of materials

Chercheurs / Enseignants-chercheurs

PhD and post-docs

Alexis BURR (2017)

Thibaut DESSOLIER (2018)

Oguz OZDEMIR (2022)

Loïcia GAUDILLIERE (2022)

Pauline GRAVIER (2019)

Paul HERVIER (2017)

Shrey JOSHI (2018)

Alexis LENAIN (2017)

Camila MALLMANN (2016)

Jessica MUZY (2020)

Oguz OZDEMIR (2022)

Yves PAQUETTE (2017)

Samir ROY (2015)

Prasanta SARKAR (2019)

Amani TLILI (2017)

Thibaut DESSOLIER (2018)

Oguz OZDEMIR (2022)

Loïcia GAUDILLIERE (2022)

Pauline GRAVIER (2019)

Paul HERVIER (2017)

Shrey JOSHI (2018)

Alexis LENAIN (2017)

Camila MALLMANN (2016)

Jessica MUZY (2020)

Oguz OZDEMIR (2022)

Yves PAQUETTE (2017)

Samir ROY (2015)

Prasanta SARKAR (2019)

Amani TLILI (2017)

Collaborations

LEGI : J.-P. Franc, G. Ghigliotti, H. Djeridi, M. Riondet

ONR Global : K.H. Kim

ESRF : E. Boller, A. Rack , M. Di Michiel, M. Scheel,

MATEIS : E. Maire, J. Adrien,

Saint-Gobain : E. Gouillart,

ALSTOM ;

U.C. Louvain (L. Delannay, T. Pardoen)

ONR Global : K.H. Kim

ESRF : E. Boller, A. Rack , M. Di Michiel, M. Scheel,

MATEIS : E. Maire, J. Adrien,

Saint-Gobain : E. Gouillart,

ALSTOM ;

U.C. Louvain (L. Delannay, T. Pardoen)

Projects

ONR NICOP, LabeX TEC21, H2020 CaFE, FP7 EXOMET, ANR EDDAM, ANR TOMOSOLIDAL, ANR SIMUZAL