The tailoring of material properties requires the design of the alloy composition and of the microstructure resulting from the manufacturing process. Also environmental constraints and new regulations constantly require the adaptation or revision of alloy compositions and consequently of the manufacturing processes. Thus, materials processing of cemented carbides has been revisited with alternative binders to Co or with less strategic metallic carbides than WC, in order to optimize sintering and microstructure and ultimately the mechanical properties. Additive manufacturing by selective melting required adapting the alloy compositions to the rapid cooling rates and conversely, it made it possible to design specific microstructures in connection with the process. Finally, it was shown that the design of alloy compositions was essential for obtaining metallic glasses and controlling their properties, as it was for controlling the biodegradability of magnesium alloys for medical implants.

Design of novel cemented carbides

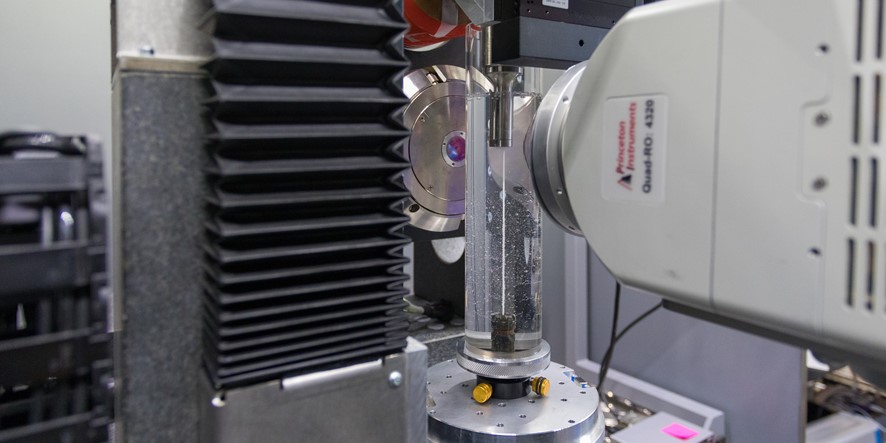

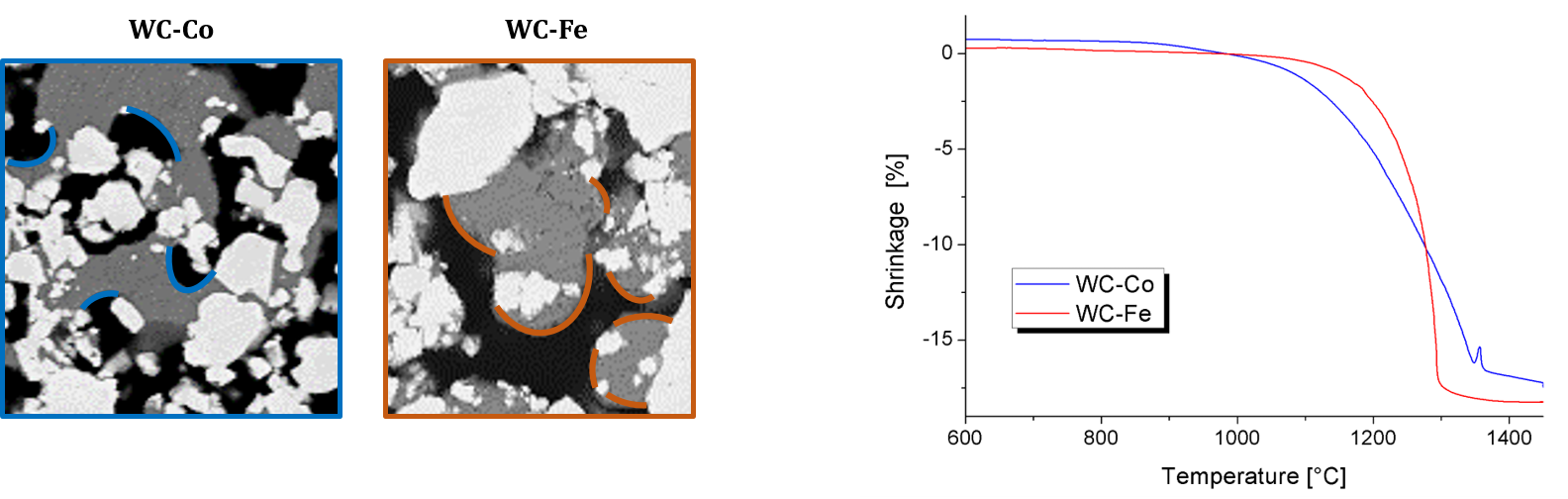

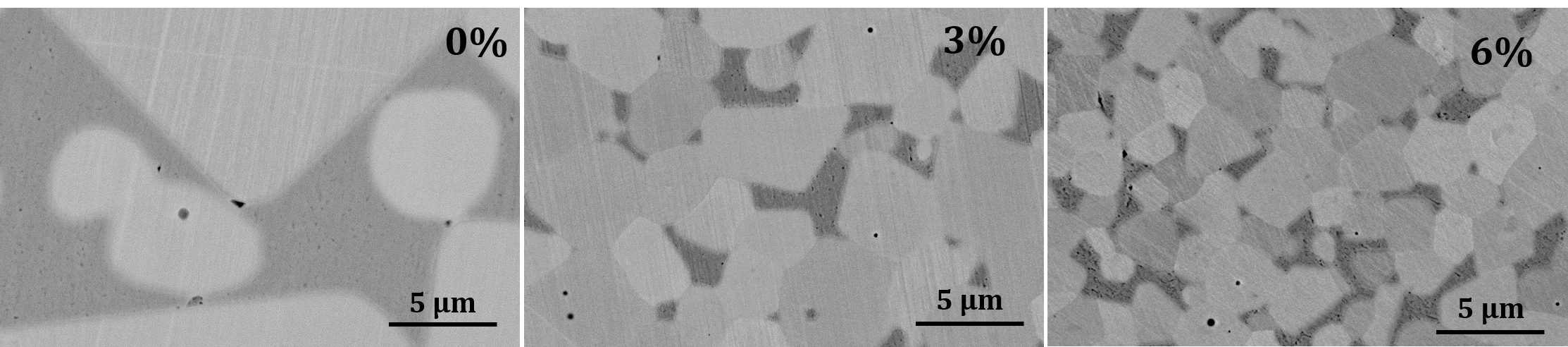

Cemented carbides are essential materials in the cutting and drilling tools industry, due to their unique combination of hardness and toughness, in relation with their microstructure. New European regulations and the hazardous supply of cobalt have put pressure on the industry to substitute Co as a binder phase in WC-Co cemented carbides. Our research has focused on the sintering and microstructure development of new WC-Fe and WC-Ni cemented carbides in comparison with conventional WC-Co. The difference in interface energies and interface structure explain the difference in solid-state sintering and in grain growth mechanisms with the different binders. Substitution of WC by a light and less expansive carbide has also been studied. This research is conducted with S. Lay (SIMAP/TOP) and is strongly supported by the carbide industry (Sandvik, Secotools and Hyperion - PhD work of Zoé Roulon and Mathilde Labonne).

Effect of favourable or non favourable solid state « wetting » and spreading on sintering, depending on the binder nature. Z. Roulon PhD. thesis (2016-2019)

Effect of favourable or non favourable solid state « wetting » and spreading on sintering, depending on the binder nature. Z. Roulon PhD. thesis (2016-2019)

Effect of the addition of MC secondary carbides on grain growth in NbC-MC-Ni cemented carbides sintered at 1450°C. M. Labonne PhD. thesis (2017-2020)

Alloys FOR AM and Microstructures BY AM ( AM = Additive Manufacturing)

Additive Manufacturing processes have received a great interest over the past few years, but there are still scientific questions to be addressed, in particular in the field of metallurgy. We aimed at improving our understanding of the effect of those new processing routes on the microstructures of the produced alloys. Our objective is two-fold.

- Developing alloys in order to make them suitable for AM-processes. Several families of alloys such as 6000-serie Al-alloy or gamma’-precipitation strengthened superalloys suffer from severe hot cracking issues. Overcoming this hot cracking issue by modifying the chemical composition while preserving or increasing the final mechanical properties is the purpose of ongoing research projects. Below is the microstructure of an Al-alloy modified to make it processable by AM.

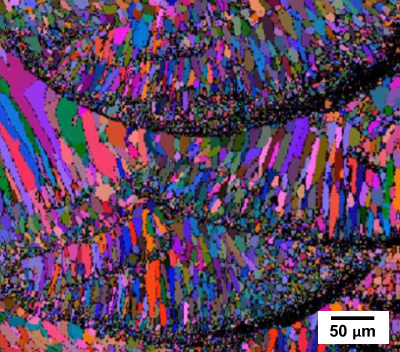

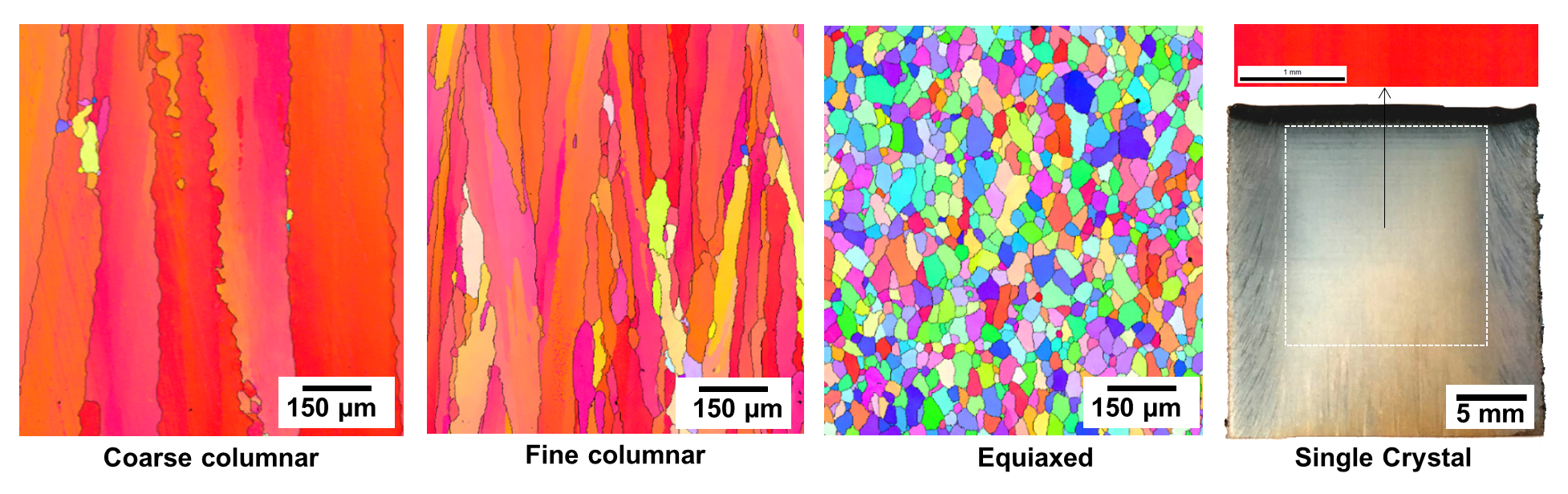

- Designing microstructures by taking advantage of the high cooling rates and of the melting strategies is another approach considered in our research activites. This approach is exemplified with the help of the illustration below showing how the microstructures of Ni-based superalloys fabricated by Electron Beam Melting can be tailored. Microstructural design of aluminium alloys fabricated by WAAM (Wire Arc Additive Manufacturing) is also under investigation, in collaboration with G-SCOP laboratory.

Additive Manufacturing of non-weldable Ni-based superalloys by Electron Beam Melting. Edouard Chauvet PhD. Thesis (2014-2017)

Additive Manufacturing of non-weldable Ni-based superalloys by Electron Beam Melting. Edouard Chauvet PhD. Thesis (2014-2017)

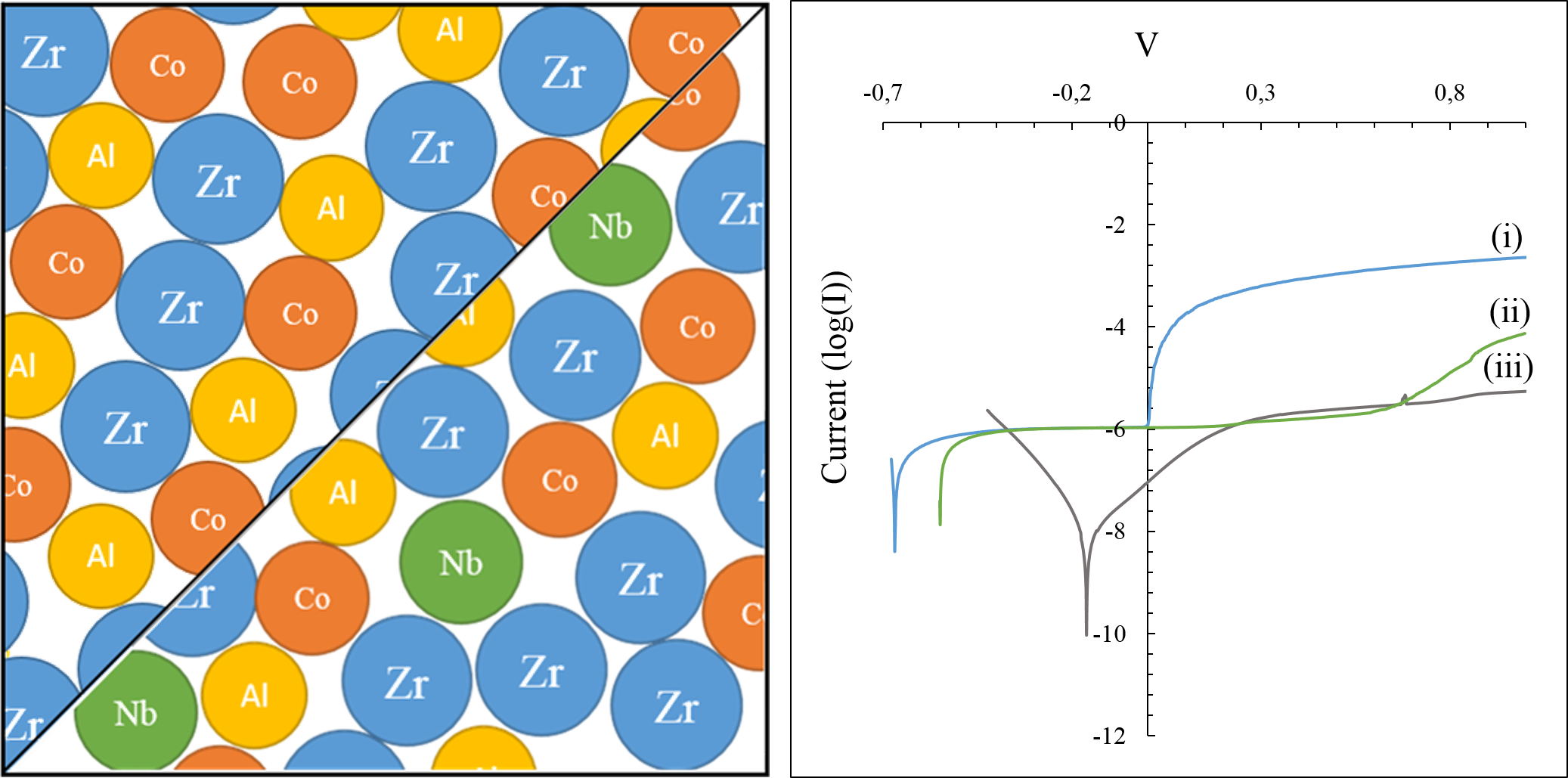

Alloy design for metallic glasses

Since the development of rapid cooling solidification techniques, bulk metallic glasses (BMG) have attracted much attention for industrial applications. Thanks to the amorphous structure and therefore the lack of defects linked to crystalline structures (e.g. dislocations, grains boudaries etc.), BMG exhibit peculiar properties. Among them, one can mention high strengh, good hardness or excellent micro moulding ability (down to a few micrometers) as well as appealing biocompatibility making them of particular interest for medical applications. Yet improvments in terms of properties are still numerus. In order to improve corrosion resistance, we have performed Nb micro-alloying on a ZrCoAl amorphous alloys. This greatly improved corrosion behaviour in saline solution, closing the gap with titanium alloys.

(left) schematic representation of the Nb micro-alloying, (right) polarisations curves of (i) ZrCoAl BMG, (ii) ZrCoAlNb BMG and (iii) TA6V. Thesis Eliott Guerin (2018-2021)

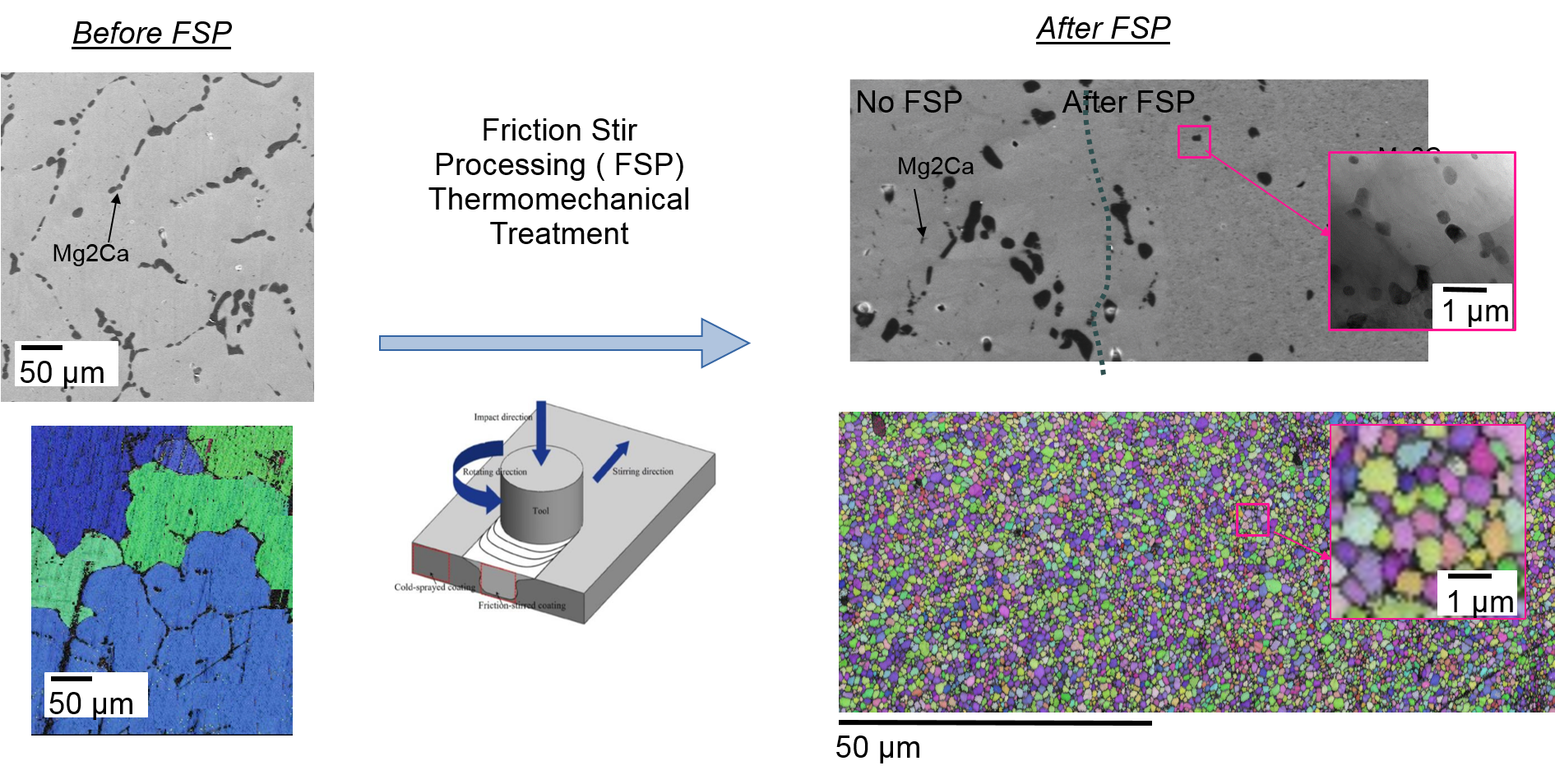

Controlling the biodegradability of Mg alloys

- Z. Roulon, J.M. Missiaen and S. Lay, Carbide grain growth in cemented carbides sintered with alternative binders. Int. J. Refract. Met. & Hard Mater. 86 (2020), in press.

- M. Pellan, S. Lay, J.M. Missiaen, Experimental study of asymmetrical tilt boundaries in WC-Co alloys, Acta Materialia 167 (2019), 197-209.

- P. Kontis, E. Chauvet, Z. Peng, J. He, A. Kwiatkowski Da Silva, D. Raabe, C. Tassin, J-J. Blandin, R. Dendievel, S. Abed, B. Gault, G. Martin. Atomic-scale grain boundary engineering to overcome hot cracking in additively manufactured superalloys. Acta Materialia 177 (2019) 209-221

- C. de Formanoir, G. Martin, F. Prima, S. Allain, T. Dessolier, F. Sun, S. Vivès, B. Harry, Y. Bréchet, S. Godet. Micromechanical beaviour and thermal stability of a dual phase a+a' titanium alloy produced by additive manufacturing. Acta Materialia 162 (2019) 149-162

- E. Chauvet, C. Tassin, J-J. Blandin, R. Dendievel, G. Martin. Producing Ni-base superalloy single crystal by selective electron beam melting. Scripta Materialia 125 (2018) 15-19

- E. Chauvet, P. Kontis, E. Jagle, B. Gault, D. Raabe,C. Tassin, J-J. Blandin, R. Dendievel, B. Vayre, S. Abed, G. Martin. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron beam melting. Acta Materialia 125 (2018) 82-94

- M. Pellan, S. Lay, J.M. Missiaen, S. Norgren, J. Angseryd, E. Coronel, T. Persson. A new insight into the ∑=2 grain boundary characteristics in WC powder and in WC-Co sintered materials, Acta Materialia 155 (2018) 172-178.

- M. Pellan, S. Lay, J.M. Missiaen, S. Norgren, J. Angseryd, E. Coronel, T. Persson. EBSD study to analyze mechanisms of phase boundary and grain boundary development in WC-Co cemented carbides. Powder Metall. 60 (3) (2017), 208-215.

- V. Bounhoure, S. Lay, S. Coindeau, S. Norgren, E. Pauty, J.M. Missiaen, Effect of Cr addition on solid state sintering of WC–Co alloys, Int. J. Refract. Met. & Hard Mater. 52 (2015), 21-28.

- M. Pellan, S. Lay, J.M. Missiaen, S. Norgren, J. Angseryd, E. Coronel, T. Persson, Effect of Binder Composition on WC Grain Growth in Cemented Carbides, J. Amer. Ceram. Soc. 98(11) (2015), 3596-3601.

- M. Ghidelli, S. Gravier, J.J. Blandin, P. Djemia, F. Mompiou, G. Abadias, J.P. Raskin, T. Pardoen, Extrinsic mechanical size effects in thin ZrNi metallic glass films, Acta Materialia 90 (2015) 232-241.

Chercheurs / Enseignants-chercheurs

PhD and post-docs

Mathis DUPORT (2022)

Arthur DESPRES (2021, post-doc)

Melek GENC (2021)

Eliott GUERIN (2021)

Paul HERVIER (2017)

Mathilde LABONNE (2020)

Alexis LENAIN (2017)

Zoé ROULON (2019)

Alizée THOMAS (2020)

Corentin VELARD (2020)

Collaborations

Université Catholique de Louvain (Belgium),

Université Libre de Bruxelles (Belgium),

Université d’Anvers (Belgium),

Chimie ParisTech (F),

Université Paris XIII (F),

Université de Rennes (F),

Hong Kong Polytechnic University,

IST Lisbon (Portugal),

Max Planck Institute Dusseldorf (Germany).

THALES

SCHNEIDER-ELECTRIC

AUBERT & DUVAL

POLY-SHAPE

CONSTELLIUM