Archy Warhol - June 2017

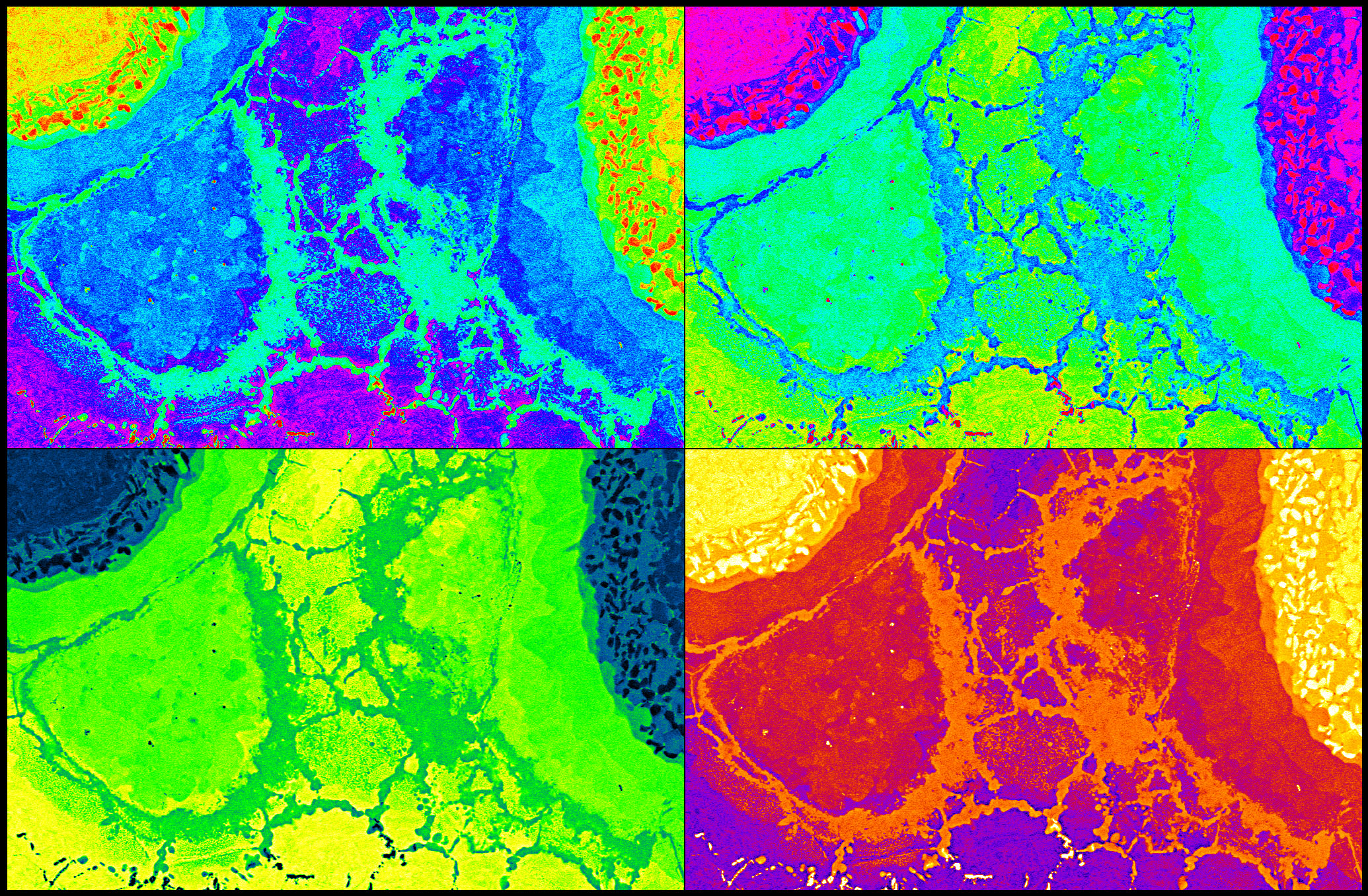

To obtain 3D architectured composites, a Ti-6Al-4V structure is manufactured using additive manufacturing (Electron Beam Melting), then the matrix is sintered around the structure using Spark Plasma Sintering. The Ti-6Al-4V / Cu composite showed here has been obtained by this process. Dense interfaces and diffusion profiles can be obtained by this process as illustrated on this pop-SEM back-scattered electrons image (x2K).

Widmanstätten patterns can be observed in the Ti-6Al-4V metal (up left and right) and large area of diffusion around interface and grain boundaries can be distinguished in the copper.

But one can see more here: an explostion, a magma... "The more you look at the same exact thing, the more the meaning goes away, and the better and emptier you feel" A. Warhol.

Widmanstätten patterns can be observed in the Ti-6Al-4V metal (up left and right) and large area of diffusion around interface and grain boundaries can be distinguished in the copper.

But one can see more here: an explostion, a magma... "The more you look at the same exact thing, the more the meaning goes away, and the better and emptier you feel" A. Warhol.

About the author : Lorene Heraud is a post-doctoral fellow in GPM2 group wherre she si studying 3D architecture composites manufactured by the combination of 3D metal printing process (EBM) and flash sintering using Joule effect (SPS).