go to actualized page: dp3D

Discrete Element Method (DEM) simulations at the length scale of particles are a powerful tool to investigate the link between microstructure and properties of particulate materials. At GPM2, we focus on DEM simulations dedicated to materials sciences with an in-house code (dp3D). The aim is to model powder processes (compaction, sintering) and to optimize the microstructure of powder-based materials. New developments with the open-source code LIGGGHTS are also under way.

Objectives

DEM simulations work at the particle length scale, thus allowing a pertinent modelling of particulate materials such as powders. The objective is to use these simulations to:

- Model powder processes such as compaction and sintering with special attention to the microstructure and its link to defect initiation.

- Optimize microstructure to ensure structural or functional properties.

Crushing agglomerates and aggregates

Uniaxial crushing of an agglomerate with dp3D

The crushing of spherical agglomerates was simulated with quantitative comparison with experiments under SEM. Crushing strength of agglomerates and aggregates can be simulated with close link to the internal structure (porosity, defects, calcination extent, …). The close-die compaction of several agglomerates can be simulated and the resulting microstructure passed to the sintering stage of the simulation code.

Sintering

a) Multilayered structured with a Nickel powder sandwiched in between two ceramic layers. b) Defects in the final Nickel layer after constrained sintering.

Sintering of complex microstructures such as composites, multilayers and powders with pore formers is tackled with DEM. For example, the constrained sintering of multilayered structures was simulated with special attention to the initiation of defects.

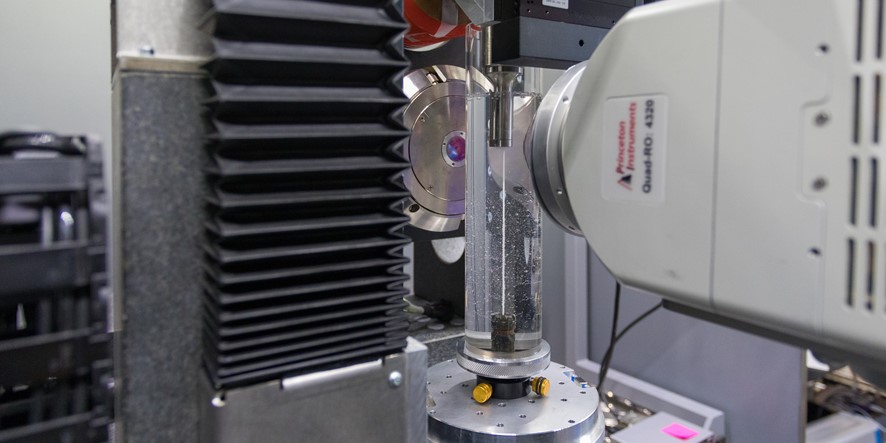

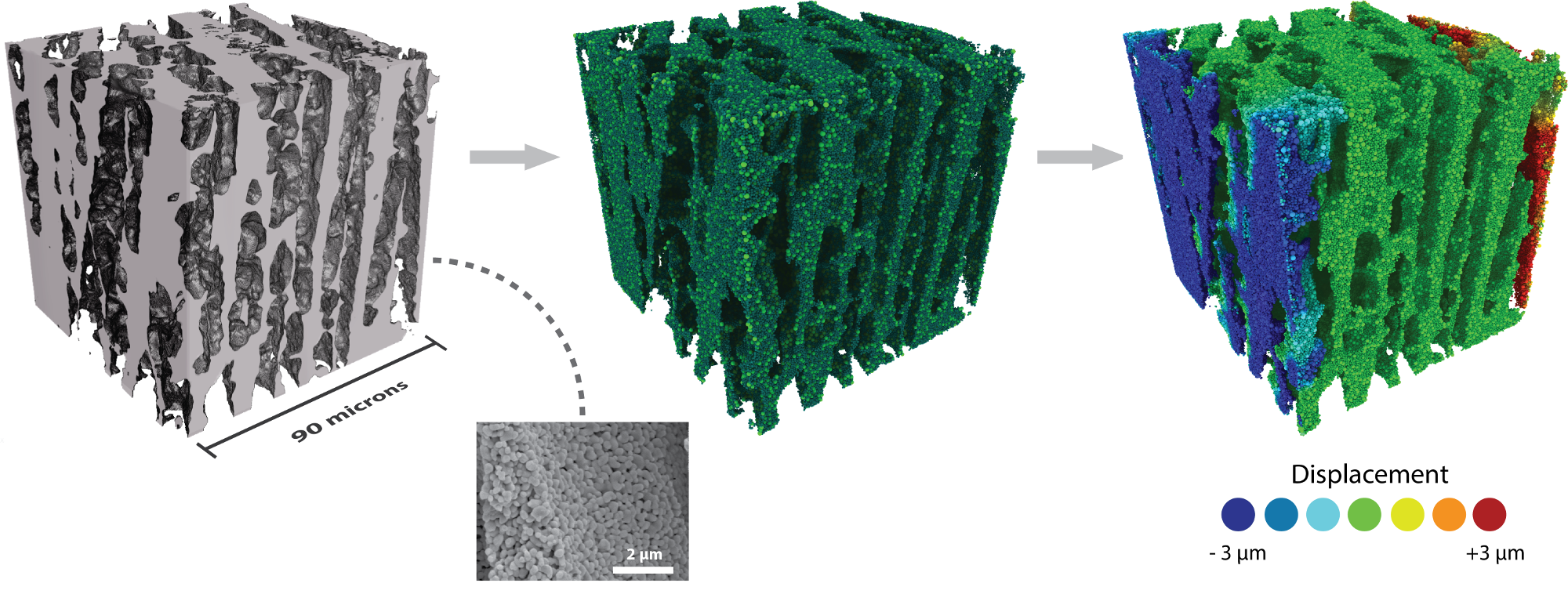

Coupling DEM and X-ray tomography

From a X-ray tomography image to a discrete element simulation of fracture of a porous ceramic obtained by freeze-casting.

DEM can advantageously be coupled with X-ray tomography to approach real microstructures. For example, sintered microstructures obtained from freeze-casting (collaboration with Univ. Washington) were imaged and given to our DEM code to obtain its fracture behavior.

Selected Publications:

- K. Radi, D. Jauffrès, S. Deville, & C. L. Martin, Elasticity and fracture of brick and mortar materials using discrete element simulations. Journal of the Mechanics and Physics of Solids 126, 101–116 (2019).

- E. Guesnet, B. Bénane, D. Jauffrès C. L. Martin, G.P. Baeza, G. Foray et al. Why fumed and precipitated silica have different mechanical behavior : Contribution of discrete element simulations. Journal of Non-Crystalline Solids. 2019

- D. Jauffrès, C.L. Martin, R.K. Bordia, Design of strain tolerant porous microstructures – A case for controlled imperfection, Acta Mater. 148 193–201 (2018).

- D. Roussel, A. Lichtner, D. Jauffrès, J. Villanova, R.K. Bordia, and C.L. Martin, Strength of hierarchically porous ceramics : discrete simulations on X-ray nanotomography images, Scr. Mater., 113 250–253 (2016).

- R. Kumar, S. Rommel, D. Jauffrès, P. Lhuissier, and C.L. Martin, Effect of packing characteristics on the discrete element simulation of elasticity and buckling, Int. J. Mech. Sci., 110 14–21 (2016).

- L. Hedjazi, C.L. Martin, S. Guessasma, G. Della Valle, and R. Dendievel, Experimental investigation and discrete simulation of fragmentation in expanded breakfast cereals, Food Res. Int., 55 28–36 (2014).

- Z. Yan, C.L. Martin, O. Guillon, and D. Bouvard, Effect of size and homogeneity of rigid inclusions on the sintering of composites, Scr. Mater., 69 327–330 (2013).

- D. Jauffrès, C.L. Martin, A. Lichtner, and R.K. Bordia, Simulation of the toughness of partially sintered ceramics with realistic microstructures, Acta Mater., 60 4685–4694 (2012).

- X. Liu, C.L. Martin, D. Bouvard, S. Di Iorio, J. Laurencin, and G. Delette, Strength of Highly Porous Ceramic Electrodes, J. Am. Ceram. Soc., 94 3500–3508 (2011).

- P. Pizette, C.L. Martin, G. Delette, P. Sornay, and F. Sans, Compaction of aggregated ceramic powders: From contact laws to fracture and yield surfaces, Powder Technol., 198 240–250 (2010).

- C.L. Martin and R.K. Bordia, The effect of a substrate on the sintering of constrained films, Acta Mater., 57 549–558 (2009).

- C.L. Martin and R.K. Bordia, Influence of adhesion and friction on the geometry of packings of spherical particles, Phys. Rev. E, 77 31307 (2008).

- C.L. Martin, G. Delette, and D. Bouvard, Compaction of ceramic aggregated powders, J. Am. Ceram. Soc., 89 3379–3387 (2006).

- C.L. Martin, L.C.R. Schneider, L. Olmos, and D. Bouvard, Discrete element modeling of metallic powder sintering, Scr. Mater., 55 425–428 (2006).

- L.C.R. Schneider, C.L. Martin, Y. Bultel, D. Bouvard, and E.Siebert, Discrete modelling of the electrochemical performance of SOFC electrodes, Electrochim. Acta, 52 314–324 (2006).

- C.L. Martin, Elasticity, fracture and yielding of cold compacted metal powders, J. Mech. Phys. Solids, 52 1691–1717 (2004).

- C.L. Martin, D. Bouvard, and S. Shima, Study of particle rearrangement during powder compaction by the Discrete Element Method, J. Mech. Phys. Solids, 51 667–693 (2003).

Chercheurs / Enseignants-chercheurs

PhD and post-docs

J. Bonaldo

G. Hamelin

B. Paredes

Collaborations

Clemson University,

Forschungszentrum Jülich Institute of Energy and Climate Research,

ESRF The European Synchrotron,

CEA

MATEIS

Projects

Mathegram

COMPASS

Funmat