Research activities related to metallic glasses are mainly focused on elaboration, thermoforming properties, capacity to get plasticity at room temperature and relation between structure and functional properties. In the recent past, a particular attention was given to a possible “scale effect” in the case of metallic glasses despite the lack of specific internal length as it can be observed for polycrystals. It has been shown that significant plasticity combined with high tensile strength could be obtained in the case of thin films in metallic glasses. In parallel, a start-up dedicated to the production of small parts in metallic glasses is under progress.

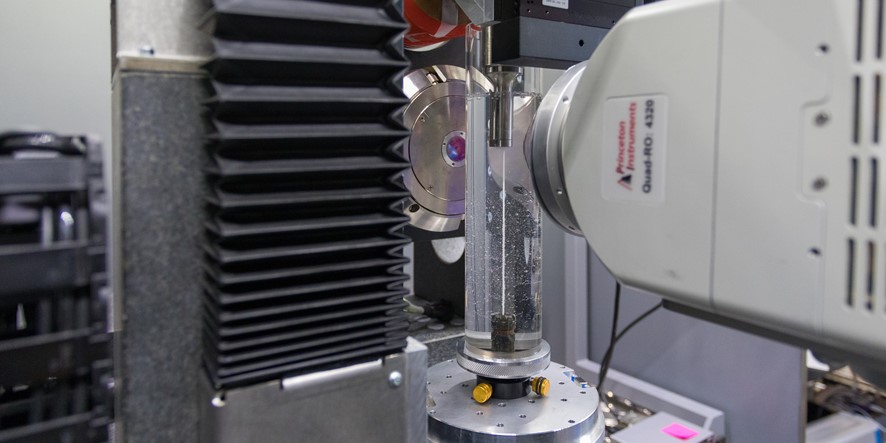

Elaboration platform and start up project

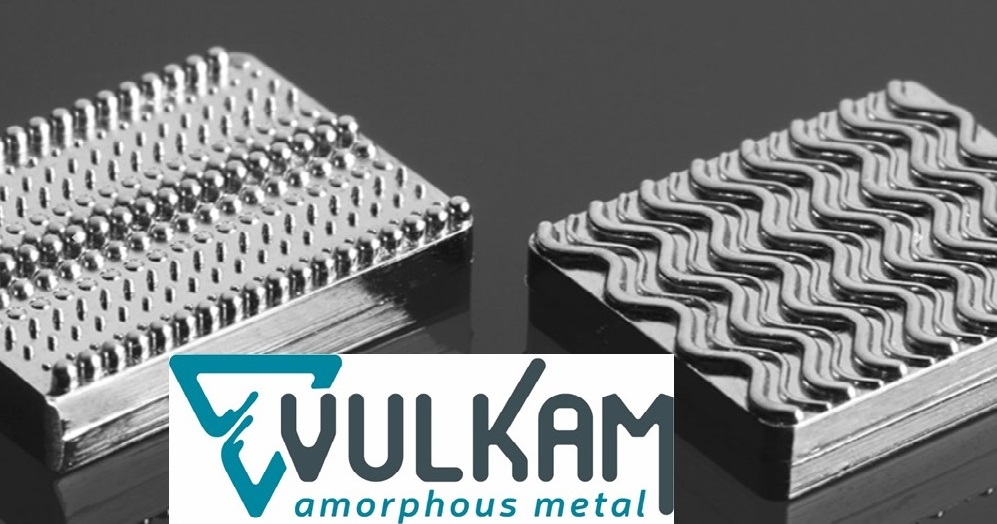

Examples of elaborated BMG components. VULKAM is the start-up now proposing processing expertise for BMG.

Bulk metallic glasses can be elaborated thanks to a dedicated elaboration platform including various equipments, like arc melting, cold and hot crucibles, suction devices, etc. Zirconium, copper or titanium based BMG are frequently elaborated. The VULKAM start-up dedicated to the production of metallic glasses small components (with complex shape) has operated since 2017.

Thermoforming properties

Example of surface relief obtained by thermoforming of a metallic glass

Metallic glasses can exhibit particularly large forming capacities when they are deformed in their supercooled liquid region (typically for temperatures larger than the glass transition temperature Tg). Mechanisms of deformation in such conditions are studied and thermoforming maps have been established for a large number of metallic glasses. Due to their lack of grains, thermoforming of metallic glasses can also result in particularly nice surfaces after deformation. This capacity can be used to induce fine surface reliefs. A study in collaboration with IST Lisbon is under progress to compare the type of reliefs that can be obtained by thermoforming and by laser processing.

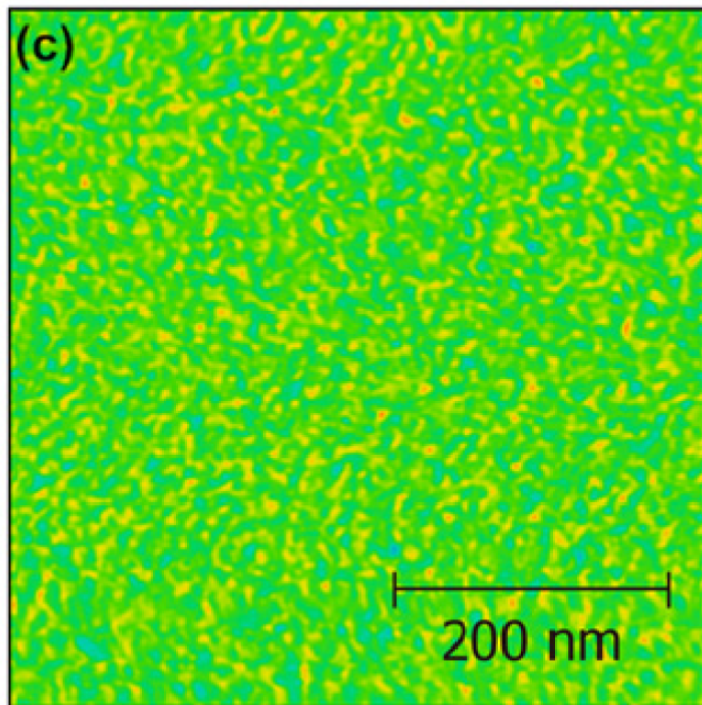

Relation between structure and properties

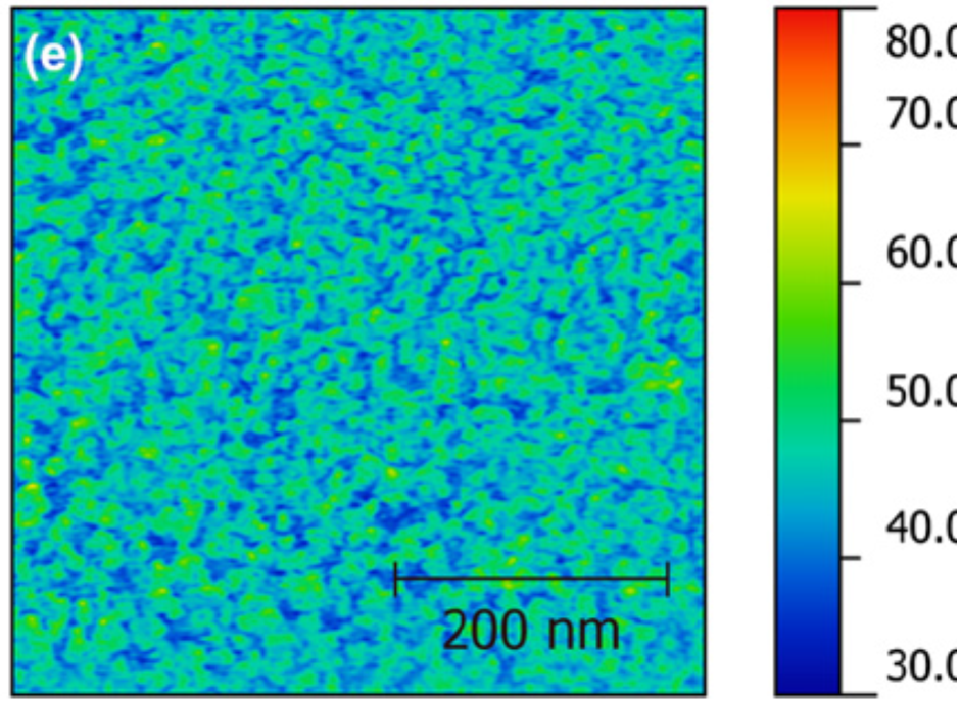

Typical density fluctuation map obtained by HRAFM before and after relaxation

Structure of metallic glasses remains an open question. High resolution atomic force microscopy techniques have shown that fluctuation in density can be clearly observed in amorphous structures and that relaxation treatments can modify significantly such fluctuations. Work is also under progress to optimize functional properties of metallic glasses, like thermal diffusivity or thermo-electricity. Effect of amorphous structure on these properties is particularly investigated and in some cases, appropriate thermal treatments are performed to elaborate amorphous / crystallite composites.

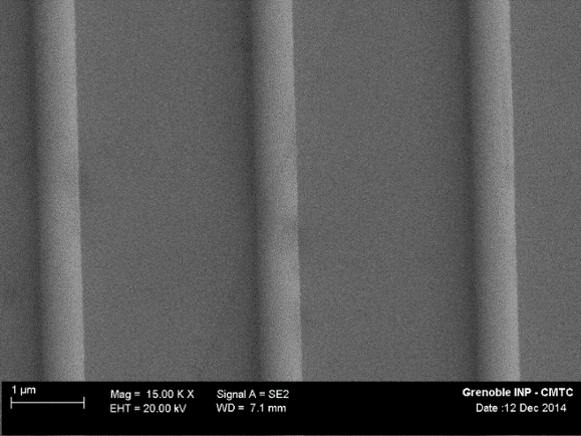

Scale effect in metallic glasses

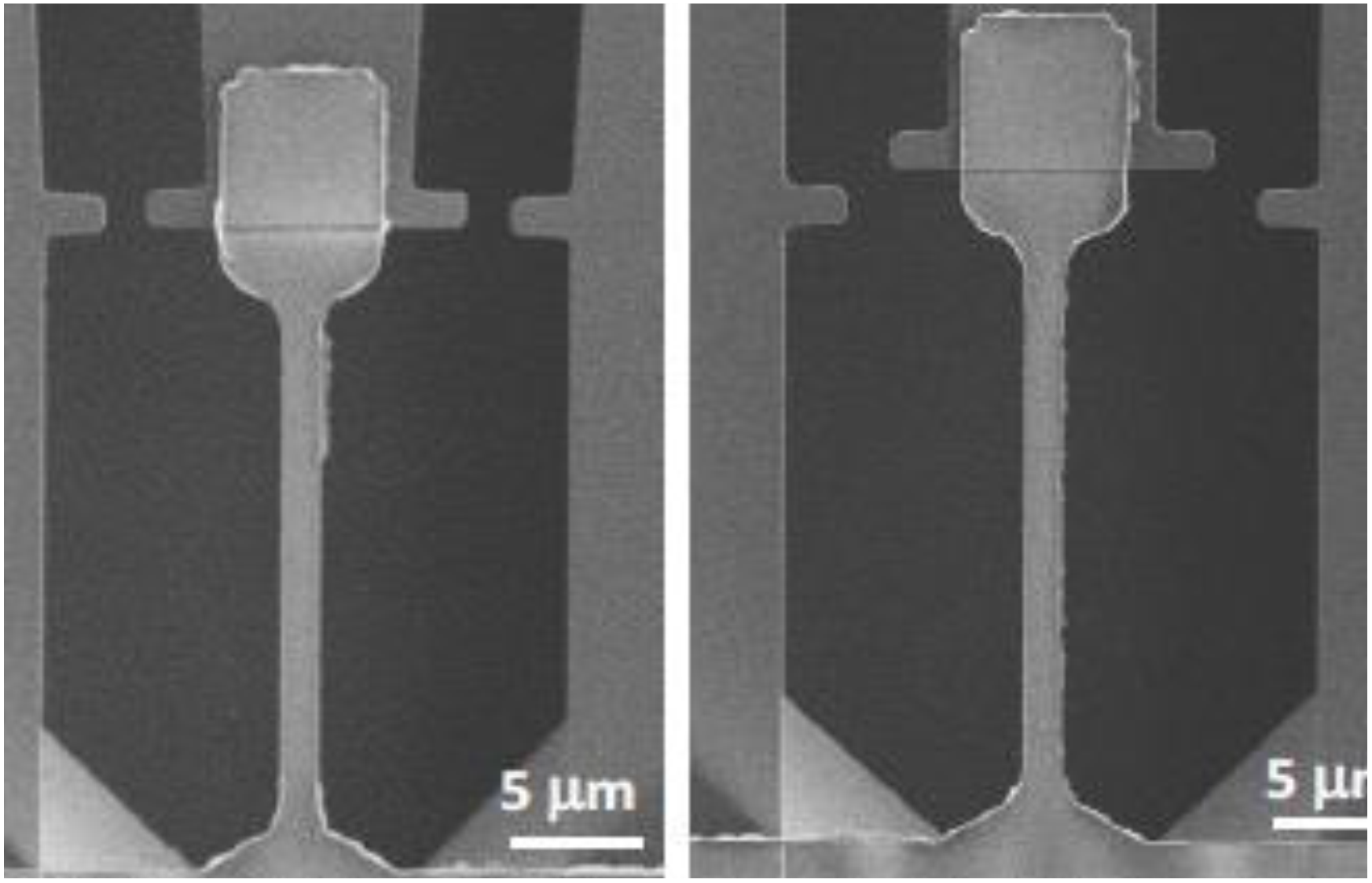

Capacity of tensile plastic deformation at room temperature of metallic glass thin film

Mechanical properties of thin films in metallic glasses have been investigated. It has been shown that high mechanical strength combined with significant plasticity in tension at room temperature could be obtained in the case of Zr based metallic glass films elaborated by PVD, which is not possible for bulk conditions. These results suggest that “scale effect” can be present in the case of metallic glasses and support the idea of the interest of thin films.

- M. Ghidelli, S. Gravier, J.J. Blandin, P. Djemia, F. Mompiou, G. Abadias, J.P. Raskin, T. Pardoen, Extrinsic mechanical size effects in thin ZrNi metallic glass films, Acta Mater. 90 (2015) 232-241.

- M. Ghidelli, S. Gravier, J.J. Blandin, J.P. Raskin, F. Lani, T. Pardoen, Size dependent failure mechanisms in ZrNi thin metallic glass films, Scripta Mater. 89 (2014) 9-12

- M. Ghidelli, A. Volland, J.J. Blandin, T. Pardoen, J.P. Raskin, F. Mompiou, P. Djemia, and S. Gravier, “Exploring the mechanical size effects in Zr65Ni35 thin film metallic glasses,” J. Alloys Compd., 615 S90–S92 (2014).

- Y. Yang, J.F. Zeng, A. Volland, J.J. Blandin, S. Gravier, C.T. Liu, Fractal growth of dense packing phase in annealed metallic glass imaged by high resolution atomic force microscopy, Acta Materialia 60 (2012), 5260-5272.

Chercheurs / Enseignants-chercheurs

PhD and post-docs

P. Hervier,

B. Lavisse,

A. Lenain,

X. Cerruti,

N. Mendil

Collaborations

Université Catholique de Louvain (Belgium),

Université d’Anvers (Belgium),

Université Paris XIII (F),

Université de Rennes (F),

Hong Kong Polytechnic University,

IST Lisbon (Portugal).